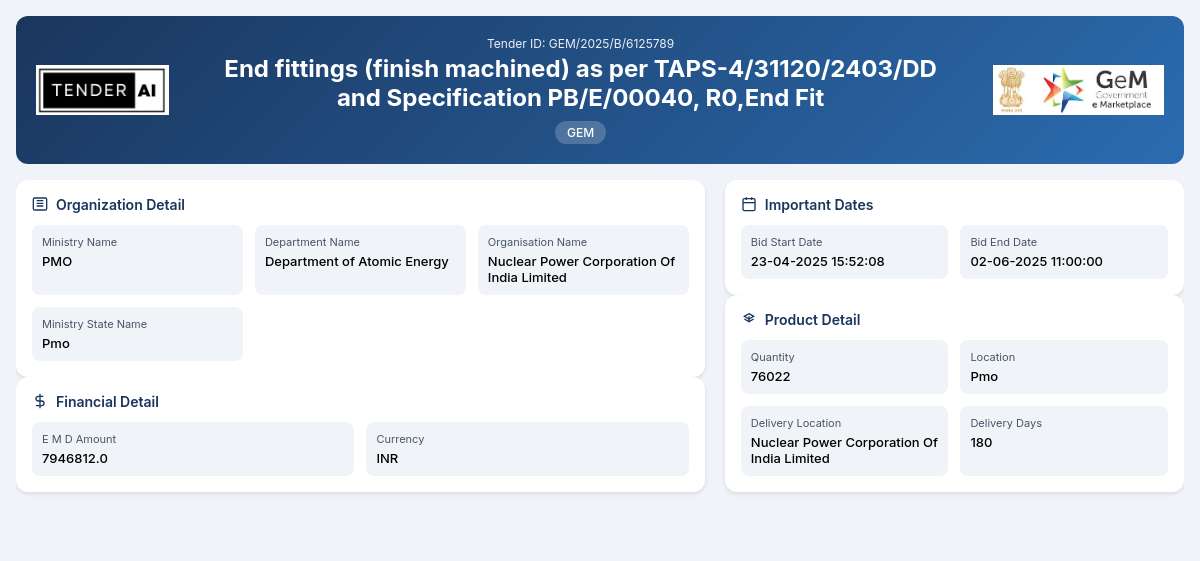

Department of Atomic Energy Tender by Nuclear Power Corporation Of India Limited (GEM/2025/B/6125789)

End fittings (finish machined) as per TAPS-4/31120/2403/DD and Specification PB/E/00040, R0,End Fit

Tender Timeline

Tender Title: End fittings (finish machined) as per TAPS-4/31120/2403/DD and Specification PB/E/00040

Issuing Authority

The tender is issued by the Department of Atomic Energy, under the Prime Minister's Office (PMO). This esteemed department is responsible for atomic energy-related initiatives and ensuring the swift and efficient operation of such projects.

Scope of Work and Objectives

This tender encompasses the supply of end fittings that are to be finish machined and developed as per the detailed specifications outlined in TAPS-4/31120/2403/DD and Specification PB/E/00040, R0. The project primarily involves the procurement of approximately 76,022 units of various end fittings, including components such as:

- End Fitting Flange for Coolant Tube rolling

- Mock-up components for CS ring shrink fittings

- Lattice Tubes for multi-channel mock-ups

- Various other fittings as specified in the listed drawings

The objective is to enhance operational efficiency in ongoing atomic energy projects while adhering to the highest standards of quality and precision.

Eligibility Criteria

To qualify for participation in this tender, bidders must meet the following eligibility criteria:

- Be a legally registered entity capable of fulfilling the procurement needs.

- Possess prior experience in handling similar scale projects and manufacturing end fittings per technical specifications.

- Demonstrate financial capability and stability to ensure successful execution of the contract.

Technical Requirements

All submissions must adhere to strict technical specifications, which include:

- Compliance with drawings specified in TAPS-4/31120/2403/DD and other referenced specifications.

- Assurance of quality standards specified by the issuing authority.

- Bidders must provide detailed descriptions of the manufacturing processes, material specifications, and quality control measures integrated into their production line.

Financial Requirements

Bidders will have to demonstrate their financial strength by providing:

- Audited financial statements for the past three years.

- Any required Earnest Money Deposit (EMD) details for submission in compliance with the tender norms.

- A breakdown of costs associated with the project to exhibit transparency in pricing.

Document Submission Details

Interested bidders must submit their proposals including all relevant documents electronically. The submission must include:

- Technical proposal along with proof of compliance with eligibility criteria.

- Financial proposal detailing all price components.

- Any additional documents that validate the qualifications mentioned above.

Special Provisions

This tender includes special provisions for Micro, Small, and Medium Enterprises (MSEs) and startups, offering benefits such as:

- Price preference clauses to promote MSE participation.

- Support in documentation and application for startups within the sector.

Evaluation Process

The evaluation of submitted proposals will be conducted based on the quality of technical specifications, the pricing offered, and the bidder's demonstrated experience. Factors include:

- Compliance with technical requirements.

- Financial stability and past project performance.

- Overall project delivery timelines.

Delivery Locations

The successful bidder will be required to deliver the goods to designated sites as instructed by the Department of Atomic Energy. Specific delivery locations will be communicated during the contract award process.

Contact Information

For any inquiries related to this tender, please refer to the official contact channels of the Department of Atomic Energy. Specific contact details are available upon request from the issued tender documents.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

78 DocumentsFrequently Asked Questions

The eligibility requirements for this tender include being a registered entity with proven experience in producing end fittings to the specified standards. Bidders must also demonstrate financial stability to handle large scale orders effectively.

Bidders must comply with the strict technical specifications outlined in the tender documents, including adherence to the drawings in TAPS-4/31120/2403/DD and other mentioned specifications. Additionally, bidders should provide documentation of their quality assurance processes.

The Earnest Money Deposit (EMD) is a requisite to secure bids, ensuring that bidders are committed to proceeding with the tender process. The amount and submission guidelines are specified in the tender document, necessitating careful review.

Proposals must be submitted electronically through the designated portal as specified in the tender documents. All documents, including financial and technical proposals, must be provided in accepted formats such as PDFs or Word documents to ensure compliance.

Yes, the tender includes notable benefits for Micro, Small, and Medium Enterprises (MSEs) and startups, such as price preferences and assistance in navigating the bidding process, supporting the growth of these businesses in the procurement landscape.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders