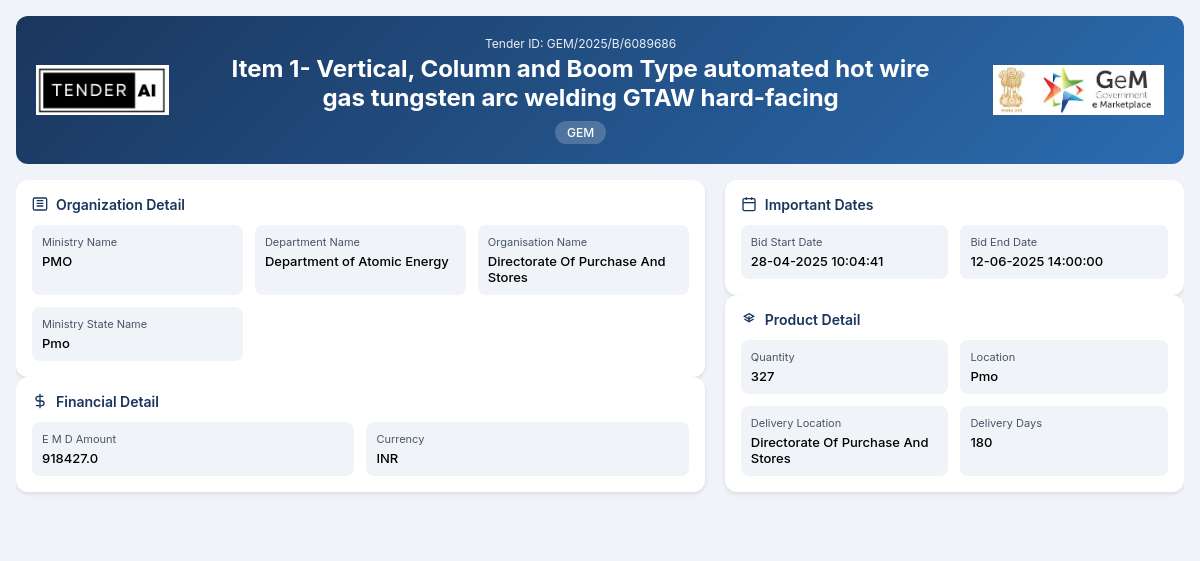

Department of Atomic Energy Tender by Directorate Of Purchase And Stores (GEM/2025/B/6089686)

Item 1- Vertical, Column and Boom Type automated hot wire gas tungsten arc welding GTAW hard-facing

Tender Timeline

Tender Title: VERTICAL COLUMN AND BOOM TYPE AUTOMATED HOT WIRE GAS TUNGSTEN ARC WELDING

Tender Reference Number: GEM/2025/B/6089686

Issuing Authority: Department of Atomic Energy

The VERTICAL COLUMN AND BOOM TYPE AUTOMATED HOT WIRE GAS TUNGSTEN ARC WELDING tender is an initiative by the Department of Atomic Energy aimed at procuring advanced welding machinery and ancillary equipment. This tender offers a significant opportunity to suppliers specializing in welding technology, particularly those focusing on Automated Gas Tungsten Arc Welding (GTAW) hard-facing applications. The scope of the work covers the delivery and installation of specialized equipment and tools, essential for seamless operations in high-precision welding processes.

Scope of Work and Objectives

The primary objectives under this tender include:

- Supply of horizontal and vertical column and boom type automated machines.

- Provision of supplementary components including gas nozzles, tungsten electrodes, and additional equipment essential for hard-facing.

This will ensure the department meets its operational requirements while enhancing efficiency and output quality in welding applications.

Eligibility Criteria

To qualify for this tender, bidders must meet the following eligibility requirements:

- Must be a registered business entity and possess relevant certifications.

- Demonstrated experience in the supply and maintenance of welding machinery and related accessories.

- Compliance with quality standards pertinent to the welding industry.

Technical Requirements

Bidders must furnish equipment and materials that conform to the specified technical standards:

- Vertical and Column Type Automated Machines must exhibit capabilities in handling diverse welding tasks and meet operational specifications such as automatic feeding and precision welding processes.

- All components like gas nozzles and tungsten electrodes must meet acceptable industry standards, exhibiting durability and high performance.

Financial Requirements

Bidders should provide a detailed financial proposal as part of their tender submission. This should include cost breakdowns for the machines and ancillary components, along with payment terms aligned with standard governmental procurement practices.

Document Submission Details

All documents related to the tender application need to be submitted in electronic format via the designated procurement portal. It is imperative for bidders to ensure that all documentation is complete and comprehensively reflects compliance with the discharge terms set out in the tender guidelines.

Special Provisions

Micro, Small, and Medium Enterprises (MSEs) and startups may benefit from provisions included in this tender, promoting competitive parity. Special allowances could be made, supporting the participation of MSEs in fulfilling this requirement, supporting the government's agenda for local procurement.

Evaluation Process

The tender evaluation will be conducted using a comprehensive framework emphasizing:

- Technical responsiveness to the project specifications.

- Financial viability and cost-effectiveness.

- Compliance with quality standards and warranty terms on equipment.

Delivery Locations

Products and services rendered under this tender must be delivered to designated facilities as outlined in the tender documentation. It is critical for suppliers to ensure timely delivery as per predetermined schedules.

Contact Information

For any inquiries or clarifications regarding this tender, the contact information will be available on the official procurement portal.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

5 DocumentsFrequently Asked Questions

The eligibility requirements include being a registered entity, having valid certifications, and demonstrating past experiences related to welding machinery supply. Bidders must also comply with national and industry-specific quality standards, ensuring they can effectively meet the operational demands set forth in the tender scope.

To participate in the tender, bidders must provide certificates that affirm their registration as a business entity, compliance with industry quality standards, and any relevant certifications related to welding equipment. These documents validate the technical competence and reliability of the suppliers.

Bidders must follow the outlined registration process on the designated procurement portal for the GEM/2025/B/6089686 tender. This involves creating an account, submitting required documents, and fulfilling all application prerequisites to establish their eligibility to bid.

Accepted document formats typically include PDF for attachments, and any forms required must be submitted in an editable format such as Word or Excel where specified. Bidders should ensure all documents are clear and legible for review purposes.

Selected bidders are expected to provide performance security in the form of a bank guarantee, which serves as a commitment to fulfilling the contractual obligations outlined in the tender. Specific details regarding the amount and format will be provided in the contract terms post-award.

This comprehensive structure, as described, ensures bidders are adequately informed and equipped to participate in the tender process successfully.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders