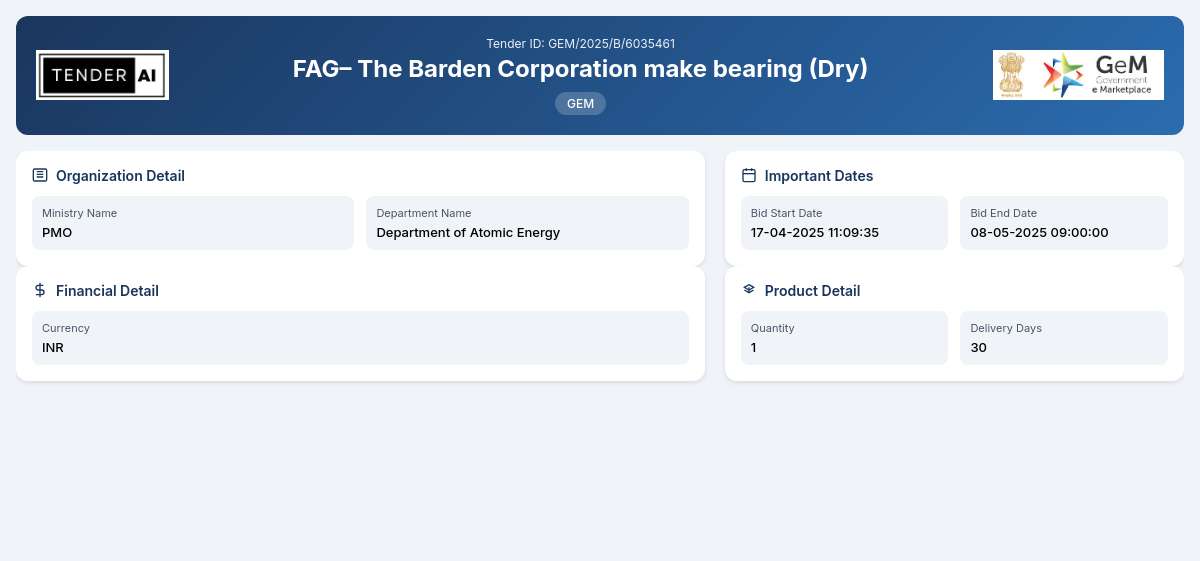

Department of Atomic Energy Tender by Nuclear Power Corporation Of India Limited (GEM/2025/B/6035461)

FAG– The Barden Corporation make bearing (Dry)

Tender Timeline

Tender Title: Supply of FAG – The Barden Corporation make bearing (Dry)

Tender Reference Number: GEM/2025/B/6035461

Issuing Authority: Department of Atomic Energy

The Department of Atomic Energy is inviting tenders for the supply of FAG – The Barden Corporation make bearing (Dry). This tender aims to procure high-quality dry bearings essential for operational efficiency in various atomic energy projects. The Department emphasizes the need for robust and reliable performance, thereby seeking suppliers who can meet stringent quality and technical specifications.

Scope of Work and Objectives

The primary objective of this tender is to acquire 7 units of FAG dry bearings. Suppliers are expected to deliver these components that conform to the prescribed specifications and standards. The bearings will be utilized in critical applications, and thus must provide superior performance reliability.

Eligibility Criteria

The eligibility requirements for submitting a bid include:

- Registration as a legal entity.

- Proven experience in supplying similar mechanical components, particularly bearings.

- Compliance with local procurement policies and quality standards.

- Submission of all required documents to validate credentials and capability.

Technical Requirements

All bids must adhere to specific technical specifications outlined in the tender documents. This includes adherence to dimensional and material standards relevant to FAG bearings. Eligible bidders must demonstrate that their products can effectively operate under the expected environmental conditions and application scenarios.

Financial Requirements

Bidders are required to present comprehensive financial documentation, including but not limited to:

- Recent financial statements.

- Tax compliance certificates.

- Detailed pricing structure, including any additional costs or potential discounts.

Document Submission Details

Interested bidders must submit their proposals in accordance with the submission guidelines specified in the tender documents. It is crucial to include all relevant certifications, technical data sheets, and proof of compliance with the eligibility criteria.

Special Provisions

The tender incorporates provisions to support Micro, Small, and Medium Enterprises (MSEs) and startups. Bidders qualifying as MSEs may benefit from certain relaxations in criteria, promoting inclusive participation in the procurement process.

Evaluation Process

Proposals will be evaluated based on the following criteria:

- Compliance with technical and financial requirements.

- Quality of submissions, including completeness of documentation.

- Price competitiveness.

The evaluation committee will review each bid meticulously to ensure adherence to specifications and support the selection of the most qualified supplier.

Delivery Locations

Successful bidders will be required to deliver the bearings to locations specified by the Department of Atomic Energy. Details regarding delivery schedules and logistics will be discussed upon acceptance of the bid.

Contact Information

For further information regarding this tender, interested parties can refer to the official communication channels provided in the tender documents. All inquiries should be directed towards the designated contact within the Department of Atomic Energy.

This tender offers an exceptional opportunity for qualified suppliers to engage with the Department of Atomic Energy, contributing to the advancement of atomic energy applications while demonstrating their expertise in mechanical component supply.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

4 DocumentsDocuments Required from Seller

- Additional Doc 1 (Requested in ATC)

- Additional Doc 2 (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered legal entity with proven experience in supplying similar components. Bidders must demonstrate compliance with local procurement policies and provide all required documentation to validate their credentials.

Bidders must conform to the specified technical specifications for FAG dry bearings, which detail the dimensional, material, and performance criteria necessary for operational reliability in demanding environments.

Bidders are typically required to submit a performance security as part of the bidding process. This guarantees the fulfilling of contractual obligations and is returned upon satisfactory completion of the contract terms.

Bidders must adhere to the specified submission methods outlined in the tender documents, which may include electronic submissions via a designated portal or physical submissions by mail. It is essential to follow these guidelines to ensure the proposal is considered.

Yes, this tender includes special provisions for Micro, Small, and Medium Enterprises (MSEs) to encourage their participation. Eligible MSEs may benefit from relaxed qualification criteria and further encouragement to engage in government contracts under the ‘Make in India’ initiative.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders