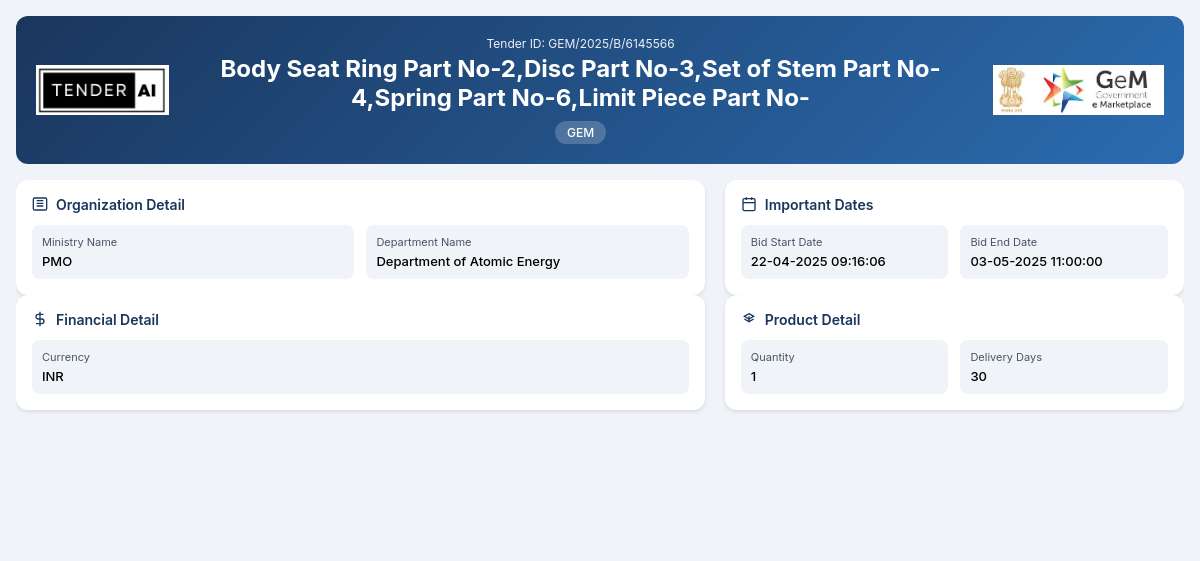

Department of Atomic Energy Tender by Nuclear Power Corporation Of India Limited (GEM/2025/B/6145566)

Body Seat Ring Part No-2,Disc Part No-3,Set of Stem Part No-4,Spring Part No-6,Limit Piece Part No-

Tender Timeline

Tender Title: SPARES FOR GATE VALVE

Reference Number: GEM/2025/B/6145566

Issuing Authority/Department: Department of Atomic Energy

The SPARES FOR GATE VALVE tender is designed to procure essential spare parts for gate valves, aimed at supporting the operational requirements of various departments within the government sector. This tender encompasses an extensive range of items crucial for the maintenance and performance of gate valves. The listed components include Body Seat Rings, Discs, Stems, Springs, Limit Pieces, Bonnet Parts, Gland Packs, and various other essential assemblies that aid in the effective functioning of gate valves.

Scope of Work and Objectives

The primary objective of this tender is to establish a reliable source for the procurement of high-quality spare parts. The successful bidder will be responsible for delivering a total of 541 units of specified spare parts, ensuring they meet technical specifications and quality standards outlined in the tender documentation. The intended delivery locations will be coordinated with the Department of Atomic Energy to ensure efficient supply chain management.

Eligibility Criteria

Bidders interested in participating must meet several eligibility requirements. These include being a registered entity under relevant government regulations, possessing experience in manufacturing or supplying similar spare components, and complying with all operational, safety, and industry standards. Additionally, bidders must demonstrate their ability to fulfill financial obligations and provide supporting documentation as per the tender’s stipulations.

Technical Requirements

Proposals must detail how the offered spare parts adhere to specified technical specifications. Bidders are expected to provide detailed descriptions of each component, including materials used, manufacturing processes, and compliance with applicable quality standards. Bid submissions should also include necessary certificates that showcase the bidders' compliance with quality standards and testing criteria.

Financial Requirements

The financial requirements for participating in this tender include submission of an Earnest Money Deposit (EMD), as well as a performance security to ensure contract compliance and fidelity to agreed delivery timelines. Bidders are encouraged to provide detailed pricing structures for the various components, including any applicable taxes and delivery charges.

Document Submission Details

Bidders must prepare a comprehensive proposal that includes all required documents. This submission should outline the qualifications, technical capabilities, and financial proposal. Bids must be submitted through the prescribed channels outlined in the tender announcement document before the close of the submission period.

Special Provisions

This tender places emphasis on enabling Micro, Small, and Medium Enterprises (MSEs) and startups to actively participate. Provisions allowing for reduced financial requirements or assistance in navigating the submission process will be available, bolstering inclusivity in governmental procurement.

Evaluation Process

The evaluation process will be conducted by a designated committee, focusing on the adherence to technical specifications, financial proposal evaluations, and bidder qualifications. Bids will be scored based on a predefined criterion that reflects the capability to deliver high-quality spare parts timely and efficiently.

Delivery Locations

Successful bidders will be responsible for delivering parts to designated locations as specified by the Department of Atomic Energy. Delivery logistics should be discussed and agreed upon following the contract award to ensure seamless integration into operational workflows.

Contact Information

For further inquiries, potential bidders should refer to the issuing department's official communications channels. Detailed contact information will be provided within the tender documentation for clarification on submission practices and eligibility.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

7 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements for participating in this tender necessitate that bidders are registered entities with relevant government bodies. Companies must also possess prior experience in supplying similar spare parts, ensuring they can meet the technical and quality requirements specified in the tender document.

Bidders must submit mandatory certificates demonstrating compliance with quality standards and technical specifications outlined in the tender. Required documents may include ISO certifications, compliance with safety standards, and any other industry-specific endorsements.

To participate in this tender, bidders must follow the registration process outlined in the procurement portal. This typically involves creating a company profile, providing compliance documentation, and ensuring that all legal and operational prerequisites are satisfied according to the tender’s criteria.

For document submissions in this tender, acceptable formats typically include PDF, Word, and Excel files. It’s crucial to ensure that all documentation adheres to the guidelines specified in the tender announcement to avoid disqualification.

The payment terms involve structured payments linked to key milestones throughout the delivery process. Moreover, a performance security will be required to ensure bidders fulfill contractual obligations. This security will serve as a financial guarantee for the timely and satisfactory completion of the project.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders