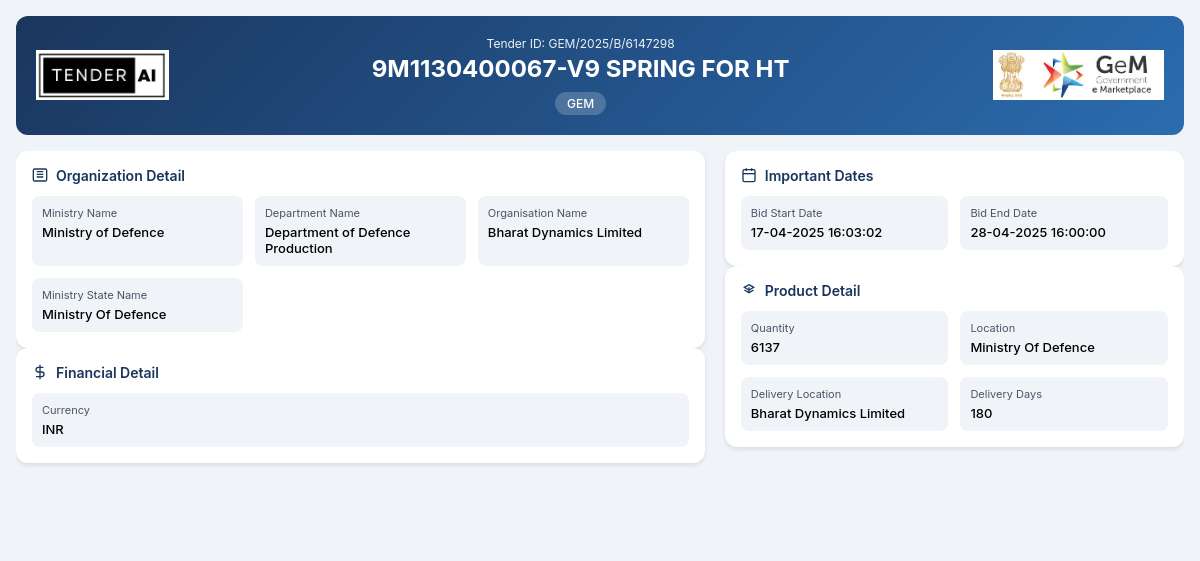

Tender Title: Supply and Delivery of 9M1130400067-V9 SPRING FOR HT

Tender Reference Number: GEM/2025/B/6147298

Issuing Authority/Department: Department of Defence Production, Ministry of Defence

The Department of Defence Production invites tenders for the supply and delivery of 9M1130400067-V9 SPRING FOR HT. This tender encompasses a significant quantity of 6,137 units, aimed at meeting the requisites of the Defence Sector. The objectives of this tender are to procure high-quality springs necessary for the specified applications, while ensuring adherence to quality standards and timely delivery.

Scope of Work and Objectives

The scope includes the manufacture, quality assurance, and delivery of 9M1130400067-V9 SPRING FOR HT. The objective is to source these components that meet precise engineering specifications and can perform reliably under varying conditions. The successful bidder will be expected to demonstrate their capacity to maintain quality control throughout the manufacturing process and logistical operations.

Eligibility Criteria

To be eligible for this tender, bidders must be registered entities, capable of supplying the specified item. Ideally, suppliers should have previous experience in similar projects, showcasing a proven track record in the production of springs as per the set quality standards. Additionally, bidders must comply with all registration norms as outlined by the Ministry of Defence.

Technical Requirements

Bidders are required to submit detailed technical specifications for the 9M1130400067-V9 SPRING FOR HT, including functionality, engineering certifications, and compliance with the specified quality assurance standards. Each submission must be supported with relevant testing data verifying the durability and reliability of the springs under operational conditions.

Financial Requirements

All bidders must provide comprehensive financial documentation including, but not limited to, previous financial statements, pricing schedules, and proof of ability to perform the contract. The submission must also include an Earnest Money Deposit (EMD) as a guarantee for the bid.

Document Submission Details

All tender submissions must be sent in the prescribed format and within the stipulated timelines. Bidders should ensure that they provide all necessary documentation to avoid disqualification. It is recommended that submissions be made electronically through the designated procurement platform to facilitate a streamlined evaluation process.

Special Provisions

In support of economic inclusivity, provisions for Micro, Small, and Medium Enterprises (MSEs) and startups have been included. Eligible entities may access simplified bidding procedures and potential concessions in EMD amounts, fostering opportunities within these sectors.

Evaluation Process

The evaluation of bids will be conducted based on predefined criteria focusing on both technical compliance and pricing. Compliance with the specified technical requirements and quality standards will be weighed heavily in the evaluation. A detailed scoring mechanism will prioritize bids that effectively demonstrate value while ensuring superior product quality.

Delivery Locations

Successful bidders will need to coordinate the delivery to designated locations as specified in the tender documents. Accurate delivery timelines must be established to align with operational needs.

Contact Information

For further inquiries regarding the tender specifics, bidders are encouraged to refer to the Department of Defence Production’s official channels for assistance.

This tender offers a significant opportunity in the procurement space, especially for companies specializing in high-quality manufacturing within the defence sector.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

4 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The qualification requirements include being a registered entity with experience in manufacturing similar items. Bidders must provide appropriate certifications demonstrating their capabilities and adherence to necessary standards. Registration with trade authorities and compliance with local procurement rules are also essential.

The required certificates typically include quality assurance certificates, ISO certifications, and any relevant compliance certifications that showcase adherence to industry standards. Documentation must confirm the technical specifications of the springs.

To participate, interested suppliers must register through the official procurement platform designated by the Ministry of Defence. The process includes creating an account, submitting business credentials, and agreeing to the terms of service as outlined in the tender documentation.

Accepted document formats for tender submission generally include PDF, DOCX, and ZIP files for any relevant technical and financial documents. It is crucial to follow the specific format guidelines provided in the tender announcement to ensure compliance.

MSEs can benefit from simplified bidding norms, reduced EMD requirements, and a supportive evaluation process that encourages participation and collaboration with larger entities. The ministry aims to enhance opportunities for MSEs within the defence procurement framework.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders