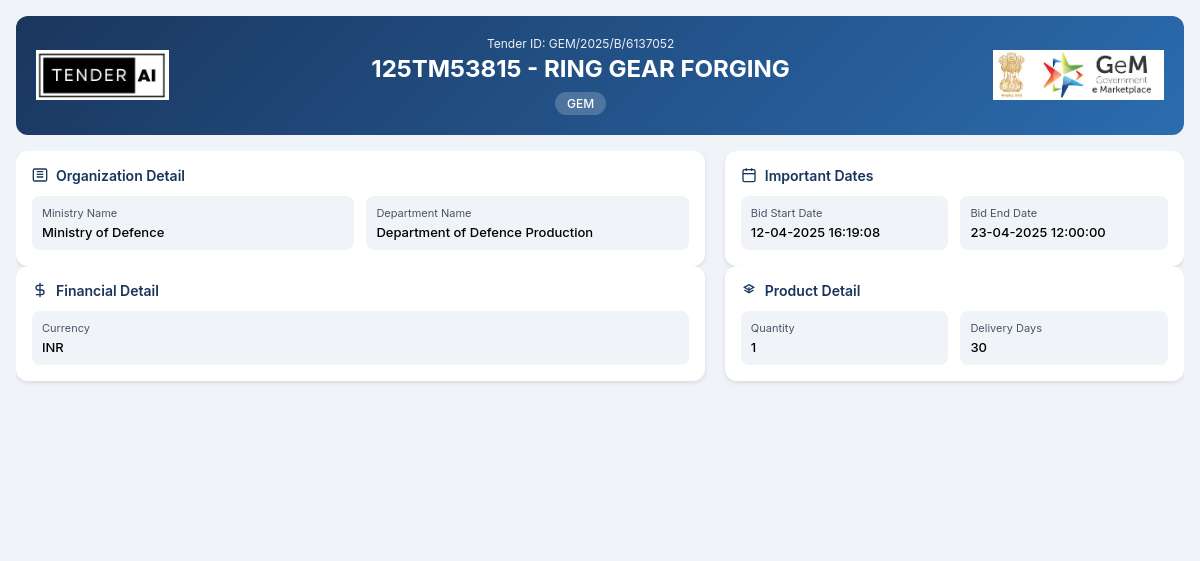

Tender Title: RING GEAR FORGING

Reference Number: GEM/2025/B/6137052

Issuing Authority: Ministry of Defence, Department of Defence Production

The RING GEAR FORGING tender invites qualified bidders to participate in supplying a total quantity of 88 units of ring gear forgings. This tender is part of a strategic procurement initiative aimed at enhancing the operational capacities of India's defense manufacturing sector. The successful bidder will be expected to deliver high-quality ring gear forgings that comply with specified technical standards.

Scope of Work and Objectives

The primary objective of this tender is to procure ring gear forgings that meet specified quality and durability standards suitable for use in military applications. The bidder must demonstrate their capability to deliver products that adhere strictly to industry standards and project specifications. The scope includes design, manufacturing, quality assurance, and delivery of the ring gear forgings within the stipulated timeline.

Eligibility Criteria

To qualify for the bidding process, participants must be registered entities fulfilling the following criteria:

- Relevant manufacturing license as per government regulations.

- Proven experience in manufacturing components for the defense sector or similar industries.

- Compliance with quality assurance certifications such as ISO or equivalent.

Technical Requirements

Bidders must ensure that the ring gear forgings meet the following technical specifications:

- Dimensions and tolerances should align with the provided drawings.

- Material quality must be high-grade steel or an approved alternative that conforms to defense sector standards.

- Capacity to perform rigorous quality testing as per defined criteria.

Financial Requirements

Bidders will need to provide a detailed financial proposal, which should include the cost per unit, and provisions for potential escalation on raw material prices. Financial stability demonstrated through recent financial statements may also be required.

Document Submission Details

Bidders are required to submit their proposals electronically via the designated tender portal. Submissions must include all supporting documents demonstrating compliance with technical and financial requirements.

Special Provisions

The tender encourages participation from Micro, Small, and Medium Enterprises (MSEs) and startups, providing them preferential treatment during the evaluation process to foster innovation and competitiveness in defense manufacturing.

Evaluation Process

The evaluation of bids will encompass a thorough assessment of technical capabilities and financial viability. Bidders will be scored on compliance with specifications, cost-effectiveness, and value-added services.

Delivery Locations

The ring gear forgings are to be delivered to specified locations as detailed in the tender documentation. It is crucial for bidders to account for logistics and transportation in their proposals.

Contact Information

For inquiries regarding this tender, bidders are encouraged to use the official communication channels provided in the tender documentation.

In summary, the RING GEAR FORGING tender is a pivotal opportunity for qualified suppliers to contribute to India's defense capabilities. Bidders must align with the outlined requirements and ensure compliance with all aspects of the submission process to be considered for this valuable procurement initiative.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

4 DocumentsCorrigendum Updates

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity with relevant manufacturing licenses. Bidders should showcase experience in manufacturing components, particularly within defense or similar sectors. Additionally, compliance with quality assurance certifications such as ISO is necessary to qualify for the bidding process.

Participants must ensure that the technical specifications outlined in the tender are adhered to. This includes precise dimensions, tolerances, and the use of high-grade materials. Bidders must also demonstrate compliance with stringent quality testing criteria and the ability to produce durable components suitable for military applications.

Bids must be submitted electronically through the designated tender portal. Participants are required to include all necessary documentation in accepted formats that demonstrate compliance with both technical and financial requirements to ensure a complete and competitive bid submission.

Bidders may be required to provide a performance security, which acts as a guarantee for the fulfillment of contract terms. This security ensures that the successful bidder will deliver as agreed, with the terms clearly outlined in the tender documents. Participants are advised to verify the specific amount and conditions for the security prior to submission.

Micro, Small, and Medium Enterprises (MSEs) can expect several benefits as a result of their participation, including preferential evaluation during the selection process. The tender encourages the engagement of MSEs to foster innovation while adhering to policies that support local manufacturing and compliance with the ‘Make in India’ initiative.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders