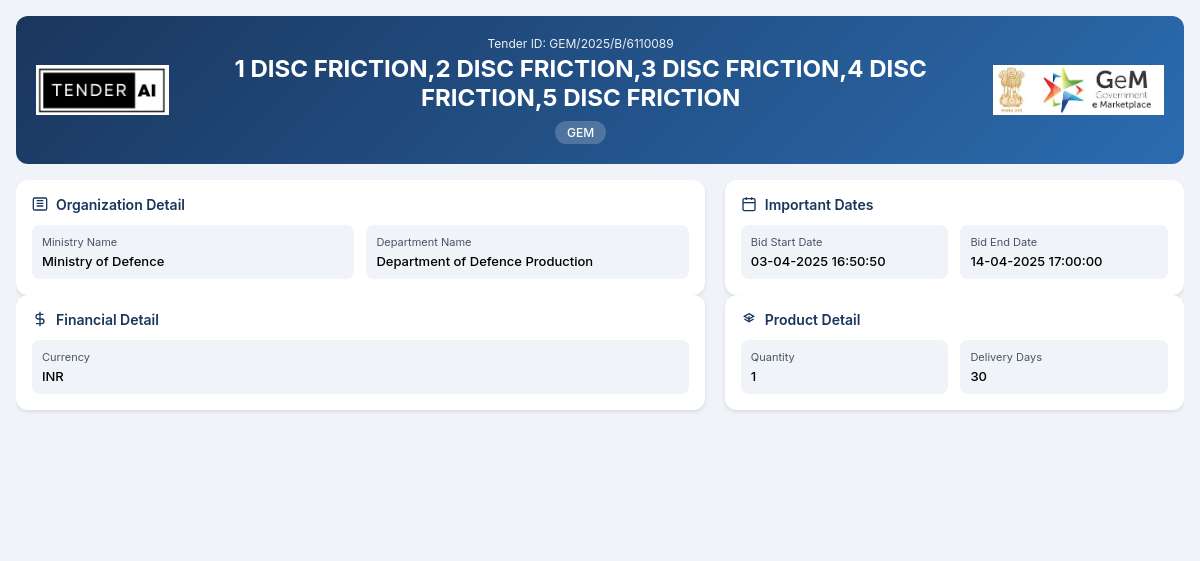

Department of Defence Production Tender by Bharat Earth Movers Limited (beml) (GEM/2025/B/6110089)

1 DISC FRICTION,2 DISC FRICTION,3 DISC FRICTION,4 DISC FRICTION,5 DISC FRICTION

Tender Timeline

Tender Title: 1200319262 DISC FRICTION

Reference Number: GEM/2025/B/6110089

Issuing Authority/Department: Department of Defence Production, Ministry of Defence

The Department of Defence Production under the Ministry of Defence has issued this tender for the supply of DISC FRICTION components essential for various defence applications. This tender is classified under the category of friction components, specifically including types 1 to 5 for DISC FRICTION. With a bidding opportunity available for a total quantity of ten units, the primary objective revolves around fulfilling the operational demands for reliable mechanical components used by defence establishments.

Scope of Work and Objectives

The scope encompasses the procurement of high-quality DISC FRICTION items, tailored to meet stringent performance standards. Suppliers must ensure that the products meet specified technical requirements and certifications, crucial for maintaining operational readiness. The successful bidders are expected to deliver these components to designated locations as specified by the ministry.

Eligibility Criteria

To participate in this tender, bidders must be registered entities compliant with the eligibility prerequisites set forth by the issuing authority. They should demonstrate technical expertise, relevant experience, and adequate resources to fulfill the tender’s demands efficiently.

Technical Requirements

The technical specifications for the DISC FRICTION components will cover material durability, size, and compatibility with existing defense mechanisms. Bidder submissions must include comprehensive product descriptions, quality certifications, and adherence to industry standards.

Financial Requirements

Bidders must provide financial documentation, including audited financial statements, to reassure their capability to execute the contract. A commitment to competitive pricing is essential, aligning with best practices in procurement.

Document Submission Details

Submission of documents must occur via the designated procurement portal. All necessary documentation, including the technical proposal, financial bid, and compliance certificates, must be submitted as per the guidelines laid out in the tender documentation.

Special Provisions

This tender encourages participation from Micro, Small, and Medium Enterprises (MSEs) and startups, recognizing the significance of fostering local procurement capabilities and supporting domestic industries. Specific incentives may be available, outlined in detail within the tender documents.

Evaluation Process

The evaluation will be conducted based on the submitted proposals' technical and financial aspects, measured against predefined criteria for quality, cost-effectiveness, and delivery timelines. The process assures a transparent selection of vendors capable of meeting the Department of Defence Production requirements.

Delivery Locations

Suppliers must ensure delivery to specified installations managed by the Ministry of Defence, as indicated in the tender guidelines.

Contact Information

For any queries regarding the tender, interested parties should refer to the official contact channels listed in the tender documentation. It is important to ensure that all communications adhere to the protocols established by the department.

By addressing these vital components, stakeholders can ensure clarity and comprehensiveness in the tender submission process, contributing to successful project execution.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

5 DocumentsDocuments Required from Seller

- Experience Criteria

- Past Performance

- Bidder Turnover

- OEM Annual Turnover *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Corrigendum Updates

Similar Tenders

Frequently Asked Questions

The eligibility requirements necessitate that the bidding entity be a registered organization, demonstrating capability through documented evidence of experience in supplying similar products. Compliance with technical standards and governmental regulations is also crucial.

The technical specifications for the DISC FRICTION components must comply with high durability standards, dimensions as per military requisites, and compatibility with existing equipment. Additionally, suppliers should provide relevant quality certifications alongside their proposals.

The Earnest Money Deposit (EMD) requirements specify a monetary bid security that all participating entities must submit, assuring commitment to the tender process. Details regarding the exact amount and submission guidelines will be outlined in the full tender documentation.

Proposals for the tender must be submitted through the official procurement portal. Accepted document formats typically include PDF and other specified file types, ensuring ease of review and verification.

This tender includes provisions aimed at supporting Micro, Small, and Medium Enterprises (MSEs), such as operational incentives and simplified compliance requirements. This alignment with the ‘Make in India’ initiative encourages domestic participation in defence procurement.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders