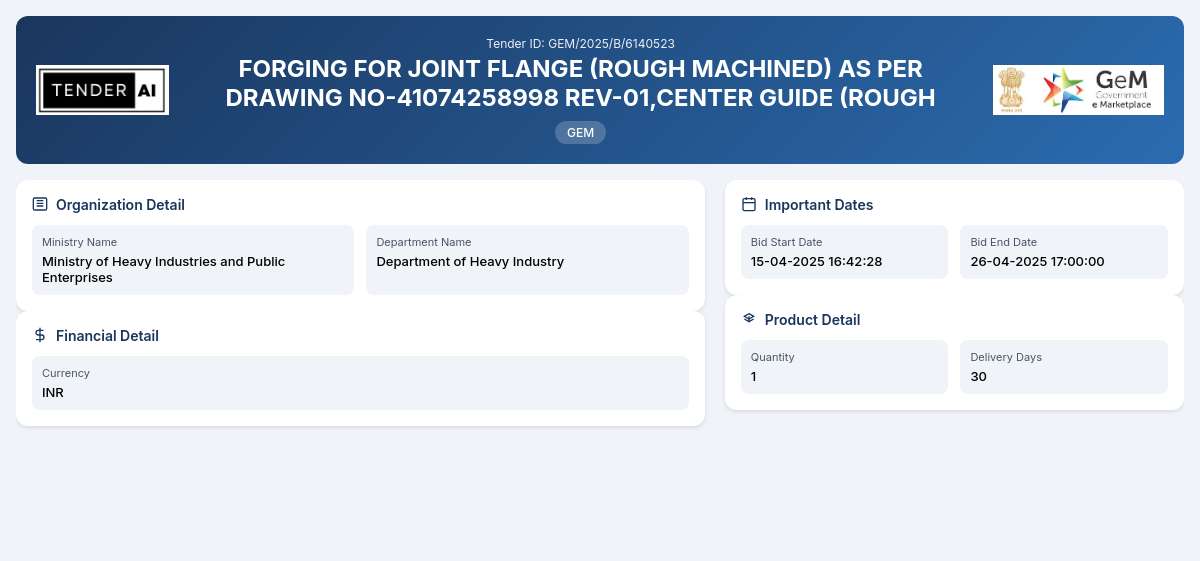

Department of Heavy Industry Tender by Bharat Heavy Electricals Limited (bhel) (GEM/2025/B/6140523)

FORGING FOR JOINT FLANGE (ROUGH MACHINED) AS PER DRAWING NO-41074258998 REV-01,CENTER GUIDE (ROUGH

Tender Timeline

Tender Title: Forging for Joint Flange (Rough Machined)

Reference Number: GEM/2025/B/6140523

Issuing Authority

Department of Heavy Industry

Ministry of Heavy Industries and Public Enterprises

Scope of Work

The scope of this tender involves the supply of forging components for joint flanges and center guides as per detailed specifications outlined in the provided drawings. This procurement will cover various components which include:

- Joint Flange (Rough Machined) as per Drawing No. 41074258998 Rev-01

- Center Guide (Rough Machined) per Drawing No. 31074158999 Rev-00

- Round Forging (Rough Machined) as per Drawing No. 41076258220F

The overall objective is to ensure a reliable supply chain of quality forging items to meet the operational demands of the Ministry.

Eligibility Criteria

Eligible bidders must be registered entities capable of offering the required products and services, along with relevant certifications to demonstrate their competency in forging manufacturing standards. Potential bidders should possess adequate experience in handling similar projects.

Technical Requirements

Bidders need to provide detailed documentation showcasing compliance with the technical specifications stipulated in the drawings. This includes adherence to relevant quality standards enforced within the forging industry as well as a proven track record of reliability in prior contracts.

Financial Requirements

Bidding entities must possess sufficient financial capacity to manage the production and supply of 32 units of the specified forging items. Details of the financial standing, including bank statements or prior financial audits, may be requested during evaluation.

Document Submission Details

- Bidders are required to submit their proposals electronically through the designated online platform.

- All necessary documents evidencing compliance with the technical and financial requirements must be included with the submission.

Special Provisions

Micro, Small, and Medium Enterprises (MSEs) may benefit from provisions set aside for their participation in this tender, ensuring greater accessibility and competition among diverse businesses. Startups may also receive special consideration in the evaluation process under the guidelines set by the Ministry.

Evaluation Process

Proposals will be evaluated based on technical and financial criteria to ensure only competent bidders are selected. The evaluation will assess the quality of compliance with technical specifications, pricing, and the reliability of delivery timelines.

Delivery Locations

The successful bidders will be expected to deliver the forging components to designated locations as specified in the tender documents post-award.

Contact Information

Though specific contact details are not provided in the documentation, bidders can generally refer to the Department of Heavy Industry for any queries related to this tender.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

18 DocumentsSimilar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity with relevant manufacturing capabilities, experience in similar projects, and possessing appropriate certifications to demonstrate compliance with industry standards. Bidders must furnish all necessary documentation while ensuring their proposals meet the technical specifications outlined in the tender.

Interested bidders must provide certificates demonstrating their compliance with industry standards and quality certifications. This may include ISO certifications, quality management credentials, and any other relevant technical certificates that reflect the applicant’s ability to meet the tender’s specifications.

Bidders need to register on the specified online platform for tender submissions. During registration, they will provide necessary company details and may need to upload documents verifying their eligibility and compliance with the technical specifications prior to proposal submission.

Payment terms will be outlined in the contract upon bid acceptance, typically involving an advance payment followed by milestones based on delivery and inspection. Performance security is mandatory and generally requires a financial guarantee that ensures compliance with contract terms; details will be clarified in the official tender documentation.

Yes, the tender includes specific provisions to encourage participation from Micro, Small, and Medium Enterprises. These entities may benefit from relaxed eligibility criteria and may receive additional support to promote inclusivity in the procurement process, aligning with current government policies aimed at bolstering MSEs and startups in competitive bidding.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders