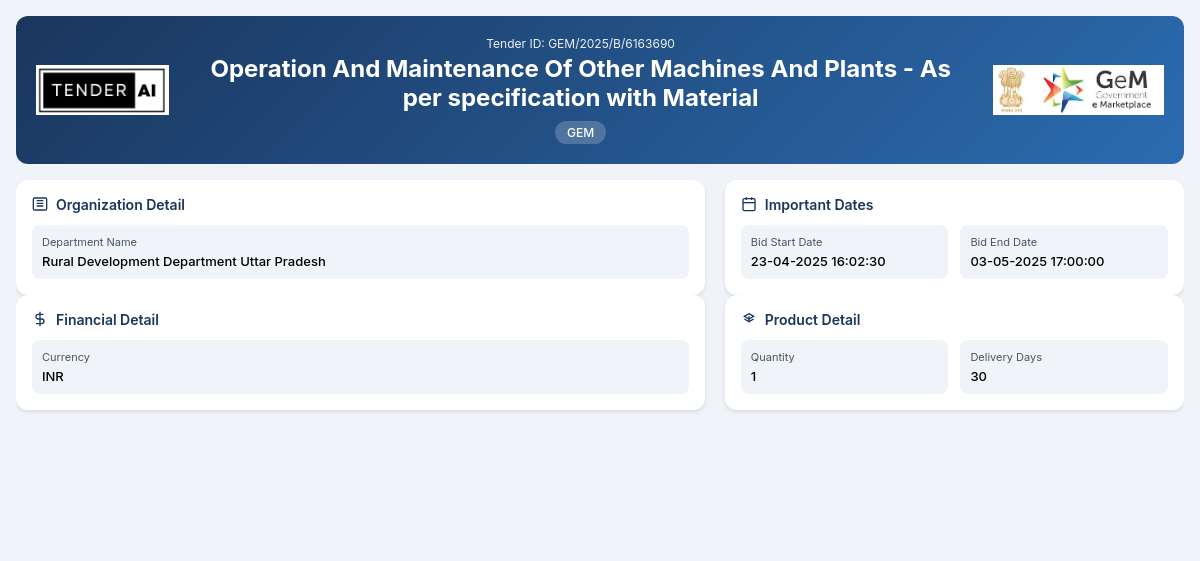

Rural Development Department Uttar Pradesh Tender by District Rural Development Agency (GEM/2025/B/6163690)

Operation And Maintenance Of Other Machines And Plants - As per specification with Material

Tender Timeline

Tender Title: Operation And Maintenance Of Other Machines And Plants

Tender Reference Number: GEM/2025/B/6163690

Issuing Authority: Rural Development Department Uttar Pradesh

The Operation and Maintenance of Other Machines and Plants tender focuses on providing comprehensive services for the upkeep and management of essential machinery and plants owned by the Rural Development Department of Uttar Pradesh. This tender is pivotal in ensuring that all operational equipment functions efficiently, ultimately supporting developmental projects across the state.

Scope of Work and Objectives

The primary objective of this tender is to secure a qualified contractor who will uphold the operational integrity of various machines and plants. The work scope includes regular maintenance, emergency repairs, and operational management to maximize efficiency and minimize downtime. The contractor is expected to deliver these services in accordance with specified technical requirements and standards.

Eligibility Criteria

Interested bidders must meet certain eligibility requirements to qualify for participation in this tender. These criteria typically include:

- Registration as a legal entity in India.

- Proven experience in the operation and maintenance sector, particularly related to machines and plants.

- Availability of necessary certifications demonstrating technical capabilities and quality compliance.

Technical Requirements

Bidders must adhere to stringent technical specifications indicated in the tender documents. This includes, but is not limited to, details around:

- Specialized equipment management.

- Maintenance protocols that align with industry standards.

- Compliance with safety and operational regulations.

Financial Requirements

A comprehensive understanding of the financial requirements is essential for potential bidders. This includes:

- Submission of a financial bid that aligns with the price evaluation criteria.

- Demonstration of financial stability to support operational commitments throughout the contract duration.

Document Submission Details

Submissions must include complete and correctly formatted documents that cover all aspects stipulated in the tender. Proper documentation ensures adherence to the submission methods outlined, which details how to submit proposals accurately.

Special Provisions

The tender includes special provisions aimed at promoting participation from Micro, Small, and Medium Enterprises (MSEs) and startups. These entities are encouraged to participate, as the government seeks to bolster local businesses and align with 'Make in India' policies.

Evaluation Process

The evaluation process will involve assessing bids based on a combination of factors including:

- Compliance with technical specifications and quality standards.

- Financial evaluation and price competitiveness.

- Experience and capabilities related to the specific services required.

Delivery Locations

Services will primarily be delivered at locations specified by the Rural Development Department across Uttar Pradesh, ensuring that equipment maintenance aligns with the department’s operational requirements.

Contact Information

For clarifications or further inquiries regarding this tender, interested parties should reach out to the Rural Development Department Uttar Pradesh, ensuring that all communication adheres to the submission guidelines provided within the tender documents.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

4 DocumentsDocuments Required from Seller

- Experience Criteria

- Bidder Turnover

- Certificate (Requested in ATC)

- Additional Doc 1 (Requested in ATC)

- Additional Doc 2 (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity in India, possessing relevant certifications in operation and maintenance, and demonstrated experience in handling similar projects. Bidders must also comply with legal norms and can expect to find detailed criteria in the tender documentation.

The technical specifications require compliance with industry standards for machinery operation and maintenance, including safety protocols, quality assurance processes, and the ability to execute maintenance jobs efficiently. It’s essential for bidders to thoroughly review the technical requirements outlined in the tender.

Participants must provide all required documentation in specified formats, ensuring compliance with submission guidelines. This documentation typically includes company registration proof, relevant certificates, and a comprehensive project proposal aligned with the evaluation criteria.

Bidders are required to submit a performance security deposit, often structured as a percentage of the contract value. This security aims to ensure the contractor’s commitment to fulfilling the terms of the contract, reinforcing the quality of service throughout the execution period.

Yes, the tender includes specific provisions that favor Micro, Small, and Medium Enterprises (MSEs) along with startups. These benefits are designed to encourage local engagement in government projects and promote compliance with ‘Make in India’ initiatives. Interested parties should refer to the tender documents for detailed eligibility and benefits.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders