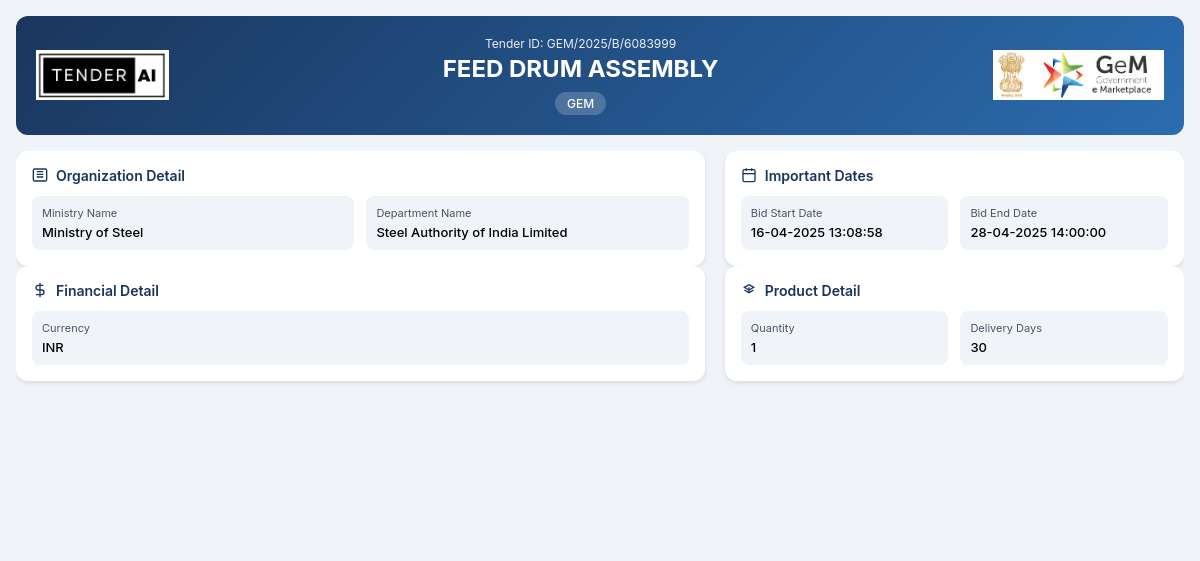

Steel Authority of India Limited Tender by Rourkela Steel Plant (GEM/2025/B/6083999)

FEED DRUM ASSEMBLY

Tender Timeline

Tender Title: Feed Drum Assembly

Reference Number: GEM/2025/B/6083999

Issuing Authority:

Steel Authority of India Limited, under the Ministry of Steel

Scope of Work and Objectives

The primary goal of this tender is to procure Feed Drum Assemblies to support operational needs. Suppliers are required to manufacture and deliver high-quality assemblies that meet rigorous industry standards. The scope of work encompasses design, fabrication, assembly, and delivery of these components, ensuring they conform to technical specifications laid out by the Steel Authority of India Limited. The objective is to enhance production efficiency and meet ongoing demand in steel manufacturing.

Eligibility Criteria

To participate in this tender, bidders must meet specific eligibility requirements, including being a registered entity in the relevant industry. Interested parties should demonstrate prior experience in manufacturing parts similar to the Feed Drum Assembly and provide references from previous projects.

Technical Requirements

All bidders must comply with stringent technical specifications, which include but are not limited to:

- Adherence to industry quality standards

- Use of approved materials for assembly

- Compliance with safety regulations during production and handling

- Capability to submit detailed technical documentation for evaluation

Financial Requirements

Bidders must present evidence of financial stability, which includes:

- Recent financial statements

- Proof of previous contracts executed that show competency in handling projects of similar magnitude

- Preparedness to submit an Earnest Money Deposit (EMD) as outlined in the submission guidelines

Document Submission Details

Interested suppliers are required to submit their proposals electronically through the designated tender portal. Each submission must include:

- A complete bid document complying with the submission guidelines

- Technical specifications and drawings of the proposed assembly

- Proof of previous experience and references

- Financial statements and EMD

Special Provisions

The tender includes special provisions aimed at promoting participation from Micro, Small, and Medium Enterprises (MSEs) and startups. Bidders meeting these classifications can avail of benefits during the evaluation process, including price preferences and relaxed eligibility criteria.

Evaluation Process

Bids will undergo a comprehensive evaluation process, focusing on:

- Compliance with technical specifications

- Financial stability and past performance

- Quality assurance and adherence to delivery timelines The evaluation criteria will favor proposals from eligible MSEs, enhancing their chances for selection.

Delivery Locations

Deliveries must be made to designated locations specified in the bid document upon award of contract. Suppliers are responsible for ensuring timely delivery as per the agreed schedule.

Contact Information

For any clarifications or inquiries regarding this tender, bidders are encouraged to refer to the official contact details provided in the tender documentation. All communications should be directed through the appropriate channels to ensure a response from the issuing authority.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

10 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC)

- OEM Authorization Certificate *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity with proven experience in manufacturing components similar to the Feed Drum Assembly. Bidders need to showcase relevant credentials, past work references, and compliance with industry standards. It is advised to thoroughly review the tender document for specific eligibility criteria to ensure your proposal meets all necessary qualifications.

Bidders must provide relevant certificates confirming adherence to quality standards and manufacturing practices that comply with the technical specifications set out in the tender. Required certifications may include ISO standards, safety compliance certificates, and any other relevant industry certifications. It’s important to review the tender details for specifics regarding the required documentation.

To participate in the registration process, interested suppliers must visit the designated tender portal, create an account, and complete the registration form. Following registration, bidders must ensure they fulfill the eligibility requirements and prepare their documentation as specified in the tender guidelines. Registering early is advisable to ensure ample time for preparation before the submission deadline.

The performance security requirements involve providing a deposit or bank guarantee post-award of contract to ensure fulfillment of contract obligations. This security is typically a percentage of the contract value and is mandated to safeguard the interests of the contracting authority. Further details regarding the exact percentage and conditions should be outlined in the tender documents.

Price evaluation considerations focus on assessing the proposed costs in relation to the overall quality and compliance with the technical specifications. The evaluation committee will compare bids based on formulated criteria and may consider the economic feasibility based on prevailing market rates. Additionally, bids from MSEs may be afforded preferential treatment to encourage participation.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders