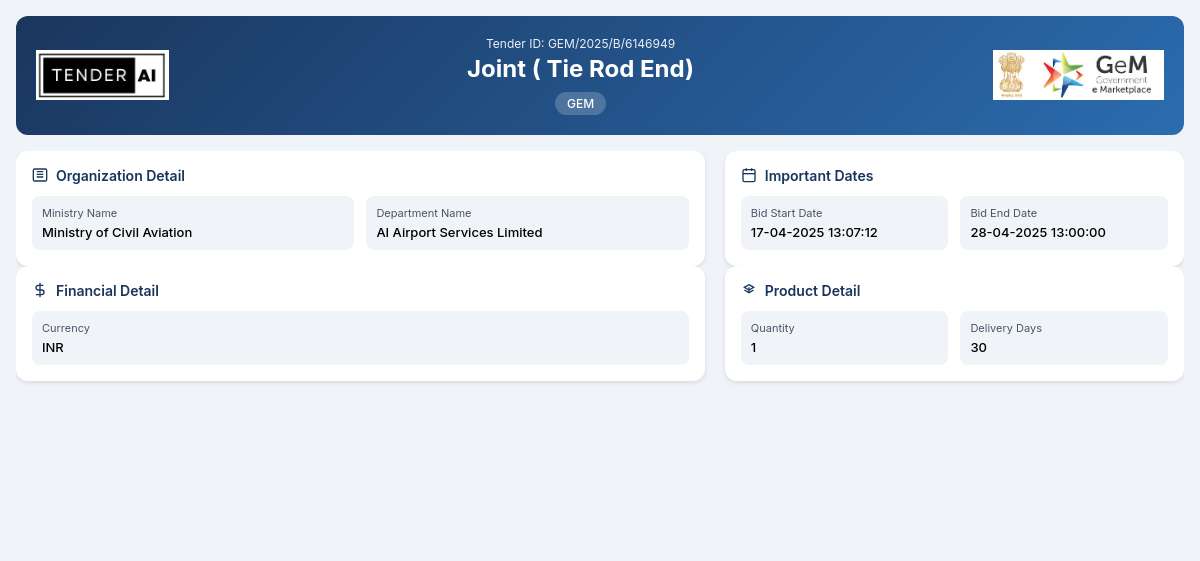

AI Airport Services Limited Tenders (GEM/2025/B/6146949)

Joint ( Tie Rod End)

Tender Timeline

Title: Joint (Tie Rod End) Tender

Reference Number: GEM/2025/B/6146949

Issuing Authority

The tender is issued by AI Airport Services Limited, under the auspices of the Ministry of Civil Aviation. This tender reflects the authority's commitment to maintaining high operational standards in civil aviation services.

Scope of Work and Objectives

The goal of this tender is to procure high-quality Joint (Tie Rod End) components for use in various applications within the civil aviation sector. The successful vendor is expected to provide eight units of these components that meet specific technical specifications and comply with industry standards. This procurement is critical to ensuring the safety and reliability of airport services.

Eligibility Criteria

To participate in this tender, bidders must comply with the following eligibility requirements:

- Must be a registered entity capable of delivering the required products.

- Must demonstrate expertise in manufacturing or supplying the Joint (Tie Rod End) components.

- Compliance with applicable local regulations and procurement standards is mandatory.

Technical Requirements

The technical requirements for the Joint (Tie Rod End) include:

- High durability and performance standards in line with aviation industry specifications.

- Provision of detailed product specifications and quality assurance protocols.

Financial Requirements

Bidders must submit financial proposals along with supporting documentation showcasing their financial capability to undertake the contract. This includes details of prior purchases and existing inventories relevant to the tender.

Document Submission Details

All documents must be submitted electronically via the designated platform before the tender closing date. Each bidder needs to ensure that their submissions are complete and adhere to the specified formats required by AI Airport Services Limited.

Special Provisions

Provisions for Micro, Small, and Medium Enterprises (MSMEs) are included in this tender to promote inclusive participation. Startups may also benefit from enhanced accessibility measures, as outlined in the government schemes that support innovation in the aviation sector.

Evaluation Process

The evaluation of bids will consider various factors, including compliance with technical specifications, financial viability, and overall value for money. The assessment will further ensure that the chosen vendor aligns with the operational needs of AI Airport Services Limited.

Delivery Locations

The delivery locations of the procured Joint (Tie Rod End) components will primarily be at designated infrastructure points managed by AI Airport Services Limited. The exact locations will be communicated to the selected vendor post-evaluation.

Contact Information

For any inquiries regarding this tender, potential bidders are encouraged to reach out to the provided contact details associated with AI Airport Services Limited. Specific contacts will be made available through the tender announcement platform.

General Information

Evaluation and Technical Information

Tender Documents

3 DocumentsSimilar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity with a proven track record in manufacturing or supplying Joint (Tie Rod End) components. Bidders must demonstrate compliance with local regulations and possess necessary certifications relevant to aviation industry standards.

The technical specifications for the Joint (Tie Rod End) require that components adhere to high durability standards, suitable for aviation applications. Vendors must provide comprehensive product specifications, outlining adherence to relevant quality standards and assurance measures during production.

Payment terms typically involve advance payments upon contract signing, with subsequent payments made upon successful delivery and inspection of the Joint (Tie Rod End) components. Compliance with pre-defined benchmarks may determine the release of final payments, ensuring accountability from the vendor.

Submissions must be made electronically through the designated tender platform, ensuring that all documentation adheres to specified formats. It is crucial for bidders to follow these guidelines strictly to ensure successful evaluation of their proposals.

Yes, this tender includes specific provisions that support Micro, Small, and Medium Enterprises (MSMEs) as well as startups, facilitating their participation. These provisions are designed to promote inclusivity and foster innovation in the supply chain within the aviation sector.

This comprehensive framework for tendering not only ensures compliance with standards but also supports local industries, enhancing the overall procurement process in the aviation sector.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders