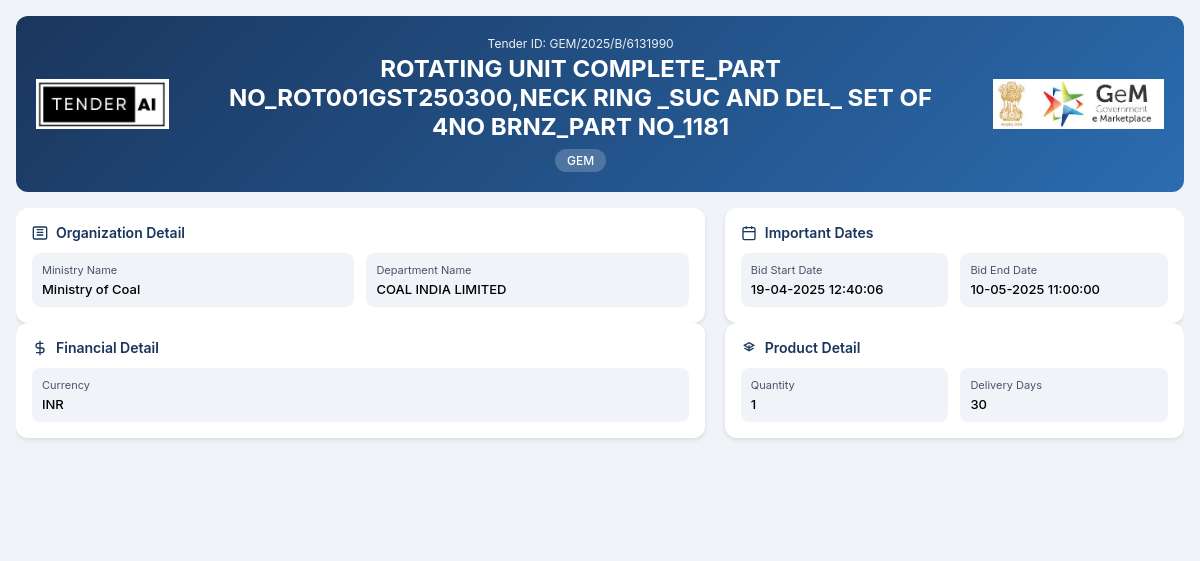

COAL INDIA LIMITED Tender by Mahanadi Coalfields Limited (GEM/2025/B/6131990)

ROTATING UNIT COMPLETE_PART NO_ROT001GST250300,NECK RING _SUC AND DEL_ SET OF 4NO BRNZ_PART NO_1181

Tender Timeline

Tender Title: Spares of M and P make Pumps

Reference Number: GEM/2025/B/6131990

Issuing Authority: Coal India Limited

Department: Ministry of Coal

Scope of Work and Objectives

This tender aims to procure a set of spare components essential for the maintenance and operation of M and P make pumps. The complete list of required spare parts includes a rotating unit, neck rings, bearing cartridges, shafts, sleeves, end covers, and various accessories designed to ensure the optimal performance of the pumps. The total quantity for this procurement totals to 224 units. The objective is to enhance the longevity and efficiency of operational assets in the coal mining sector.

Eligibility Criteria

To qualify for participation in this tender, bidders must be registered legal entities with requisite experience in supplying similar products. Bidders are also expected to demonstrate their capability to meet the technical and financial requirements as specified in the tender documentation.

Technical Requirements

Eligible bidders must provide evidence of the following technical qualifications:

- Compliance with industry standards for quality assurance.

- Availability of certified technical personnel to support supply and installation.

- Evidence of prior successful delivery of similar components in a timely manner.

Financial Requirements

Bidders must ensure financial stability and viability by submitting the following documents:

- Audited financial statements for the last three financial years.

- Proof of business registration and tax compliance.

- An Earnest Money Deposit (EMD) as specified in further detail within the tender guidelines.

Document Submission Details

All applicable documents must be submitted electronically through the designated procurement portal. Bidders should ensure that the submission adheres to the specified document format requirements.

Special Provisions

The tender provides special considerations for Micro, Small, and Medium Enterprises (MSEs) as well as start-up businesses to encourage participation from these sectors. Specific benefits and provisions are detailed in the tender documentation.

Evaluation Process

Submissions will be rigorously evaluated based on the following criteria:

- Compliance with eligibility and technical requirements.

- Competitiveness of financial proposals.

- Overall capability and experience of the bidder.

Delivery Locations

The successful bidders will be required to deliver the products to specified coal mining locations as defined within the operational frameworks of Coal India Limited.

Contact Information

For any inquiries related to the tender, interested bidders can reach out through the official communication channels provided in the tender documentation.

This comprehensive outline of the tender facilitates potential participants to grasp the essentials required for successful submission and ensures that they remain aligned with the expectations set forth by the issuing authority.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

5 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC)

- OEM Authorization Certificate

- Additional Doc 1 (Requested in ATC)

- Compliance of BoQ specification and supporting document *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered legal entity with proven experience in supplying similar spare parts. Bidders must demonstrate financial stability by providing audited financial statements for the last three years. Additionally, compliance with both technical and financial requirements must be established as outlined in the tender documentation.

The technical specifications encompass adherence to industry-quality standards and the ability to deliver components that meet the operational needs of M and P make pumps. Bidders must present evidence of preceding successful deliveries of similar parts and must also have qualified personnel for support during the installation and operation phases.

The Earnest Money Deposit (EMD) is an essential requirement to ensure the seriousness of the bidders’ participation. Bidders must submit the EMD amount as specified in the tender documents. This deposit will be refunded to unsuccessful bidders after the conclusion of the tender process, while the successful bidder’s deposit will be adjusted against the performance security.

Documents must be submitted electronically via the official procurement portal. It is crucial that supplied documents meet the specified accepted document formats outlined in the tender guidelines to ensure compliance and facilitate smooth processing.

Yes, there are benefits for Micro, Small, and Medium Enterprises (MSEs) articulated within the tender documentation. These provisions encourage MSE participation through relief measures which may include exemptions from certain fees and preferences in the evaluation process to promote inclusivity and competitiveness within the sector.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders