Tender Title: Spares of CW Chlorination Plant

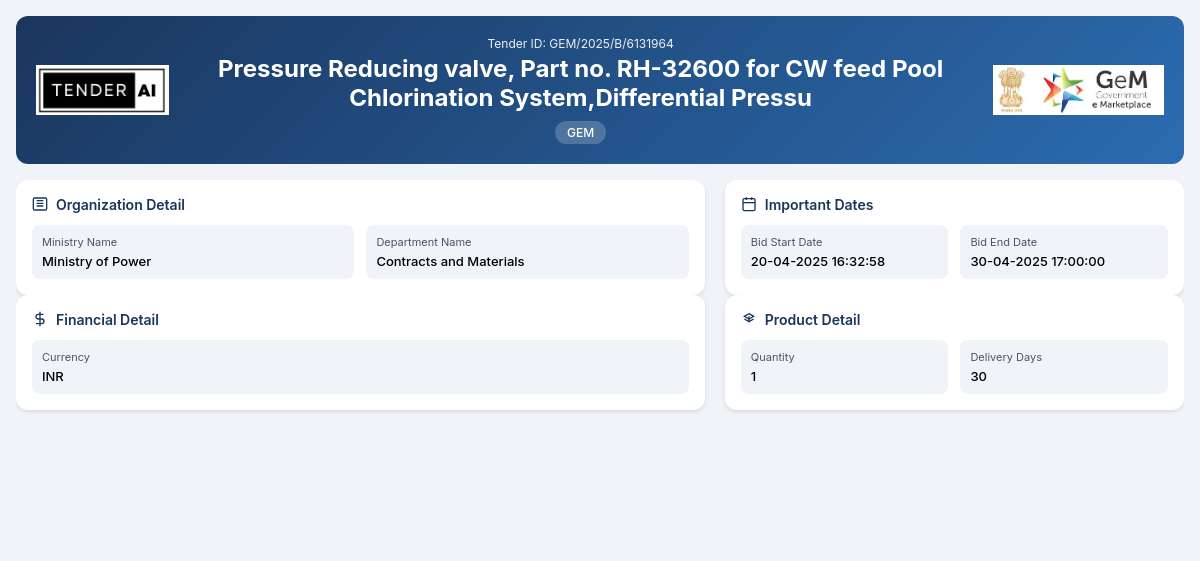

Tender Reference Number: GEM/2025/B/6131964

Issuing Authority

Ministry of Power

Department: Contracts and Materials

Scope of Work and Objectives

This tender seeks bids for the supply of specialized spare parts for the Cooling Water (CW) Chlorination Plant. The intended procurements include various vital components essential for the efficient functioning of the chlorination system, ensuring proper water treatment and compliance with health standards.

The selected vendor will be responsible for supplying the following items:

- Pressure Reducing Valve (Part No. RH-32600)

- Differential Pressure Regulator

- Various valves including flow control, vacuum relief, and isolation needle valves

- Agitators and expansion chambers

- Rupture disc, diaphragm valve, and butterfly valve

- Other critical components as specified

The overall objective is to enhance the operational capacity of the CW Chlorination Plant and ensure uninterrupted service.

Eligibility Criteria

Bidders must meet the following eligibility requirements:

- Be a registered entity with the relevant authorities

- Demonstrate experience in supplying industrial equipment or spare parts to similar projects

- Provide evidence of financial stability and capacity to deliver specified parts on time

Technical Requirements

Participants are required to furnish detailed specifications of all parts proposed for supply, including:

- Compliance with industry quality standards

- Technical specifications of spare parts

- Maintenance guidelines and operational manuals

Financial Requirements

Bidders must submit competitive pricing along with a clear pricing structure. Payment terms and conditions will be elaborated to ensure transparency and compliance with statutory regulations.

Document Submission Details

Interested bidders must submit their proposals and all required documentation via the designated online procurement portal. All bids must be submitted in accepted document formats.

Special Provisions

The Ministry provides special provisions for Micro, Small, and Medium Enterprises (MSEs) and Startups, aimed at promoting inclusive growth within the industrial supplier sector. These entities may have reduced criteria pertaining to financial capability, enhancing their opportunity to participate.

Evaluation Process

Bids will be evaluated based on a structured assessment that includes:

- Compliance with technical specifications

- Financial competitiveness

- Past performance and reliability of the supplier

The procurement committee will ensure a fair evaluation process to select the best proposals.

Delivery Locations

Successful bidders will be required to deliver to designated locations as specified by the contracting authority within the region.

Contact Information

For any inquiries related to this tender, interested parties may reach out to the Ministry of Power, Contracts and Materials Department. Specific contact details would be available upon registration on the procurement portal.

This comprehensive overview underlines critical information about the tender for the supply of spare parts for the CW Chlorination Plant. All prospective bidders are encouraged to review the eligibility criteria and submit their proposals in accordance with the guidelines outlined above.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

5 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC)

- OEM Authorization Certificate

- Additional Doc 1 (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity with appropriate licensing and experience in supplying spare parts for industrial applications. Participants should demonstrate financial stability and have a proven record of timely deliveries in past contracts. The ability to adhere to technical specifications and quality standards pertaining to the provided spare parts is also essential.

Bidders are generally required to submit certificates that validate their registration and operational capability, including a valid business license and tax compliance certificates. Quality certifications related to the supplied parts, such as ISO certification, may also enhance the bid’s credibility.

Interested vendors should register on the designated online procurement portal, providing necessary organizational details and documentation to establish their credentials. Proper documentation submission is crucial to ensure compliance with the qualifications set forth in the tender.

Submissions should include all bid documents in standard formats such as PDF, DOCX, or other specified formats indicated on the procurement portal. It is critical to follow the submission requirements to avoid disqualification.

Bidders who are awarded the contract will be required to submit a performance security to guarantee the fulfillment of contractual obligations. This security may be in the form of a bank guarantee or other approved securities, as discussed during the evaluation phase.

This FAQ section aims to clarify common concerns and enhance understanding of the tender process for all potential participants.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders