Tender Timeline

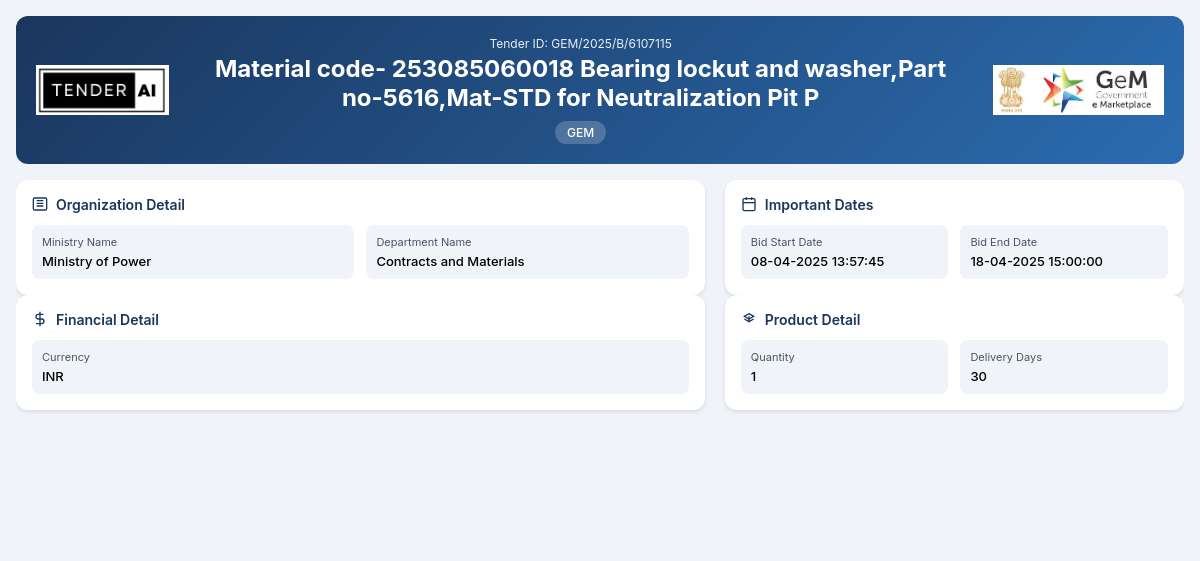

Tender Title: Procurement of complete N PIT pump and spares of N PIT pump of CPU Regeneration plant for PWS

Tender Reference Number: 327074baf

Issuing Authority/Department: Ministry of Power, Contracts and Materials

Scope of Work and Objectives

This tender aims to procure a complete Neutralization Pit (N PIT) pump along with essential spare parts for the CPU regeneration plant intended for Water Supply (PWS). The key objectives are to ensure effective operation and maintenance of neutralization systems within the facility, which is critical for optimizing water quality and performance. Bidders are expected to provide quality materials that align with the specifications laid out in this tender, ensuring efficient and reliable functioning of the systems.

Eligibility Criteria

To participate in this tender, bidders must satisfy specific eligibility requirements such as:

- Being a registered entity in India.

- Having relevant experience in similar procurements or projects.

- Meeting the technical specifications and quality standards outlined in the tender documents.

Technical Requirements

The technical requirements for the N PIT pump and its spare parts include:

- Conforming to the Material codes provided, such as Bearing lockout and washer with part number 5616, as well as applicable specifications for the Neutralization Pit Pump Model- CPP1-100 X 80 - 400 RL.

- Providing certificates to affirm the compliance of products with quality standards relevant to their respective categories.

- Meeting guidelines as prescribed for manufacture by reputable suppliers like Su Motors Pvt Ltd.

Financial Requirements

Bidders are required to submit a competitive financial proposal. Please include detailed breakdowns of costs associated with each item. There might also be provisions for an Earnest Money Deposit (EMD) which needs to be specified in the financial submission.

Document Submission Details

All documents, including bid proposals, technical specifications, and financial quotations, must be submitted as indicated in the official tender document. Submission should be made in the required format (to be specified further) to ensure compliance with the evaluation criteria.

Special Provisions

Micro, Small, and Medium Enterprises (MSEs) may avail benefits as stipulated by the Ministry of Power, promoting inclusivity in participation. Startups are also encouraged to participate under favorable terms, boosting local enterprise involvement.

Evaluation Process

The evaluation will be based on quality, compliance with technical specifications, and financial aspects. All bids will undergo a thorough review process to determine the most beneficial proposals for the project.

Delivery Locations

Successful bidders must ensure timely delivery of pumps and spare parts to specified locations within the jurisdiction of the relevant plant projects. The exact details regarding delivery sites will be communicated during the contract finalization.

Contact Information

Should you require any assistance or further clarifications, please reach out to the Ministry of Power’s Contracts and Materials department. Contact details will be made available in the final tender documents.

This tender provides an excellent opportunity for suppliers to engage with a high-value contract aimed at enhancing operational efficiency in water supply systems through quality procurement. Bidders are encouraged to thoroughly review all requirements before submitting their proposals to ensure compliance and maximize evaluation scores.

Tender BOQ Items

17 ItemsGeneral Information

Financial Information

Evaluation and Technical Information

Tender Documents

5 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Corrigendum Updates

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity in India with relevant experience in similar projects. Bidders must also demonstrate that they meet the technical specifications detailed in the tender documents.

Bidders need to provide certificates that confirm compliance with the relevant quality standards and technical specifications outlined in the bid. This includes manufacturer certifications for the specified spare parts and pumps.

The registration process involves filling out the application form available on the tender portal. Bidders must provide the necessary documentation, including proof of past experiences and compliance with technical specifications, as per the tender guidelines.

Earnest Money Deposit (EMD) is typically required to confirm genuine intent from bidders. Further details regarding the amount, submission procedures, and return policies will be clearly specified in the tender documents.

The price evaluation considerations will account for both the financial and technical proposals of each bid, ensuring that the most economically advantageous option is selected without compromising on quality or compliance with specifications. The evaluations will be conducted by the appointed committee as per the defined criteria.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders