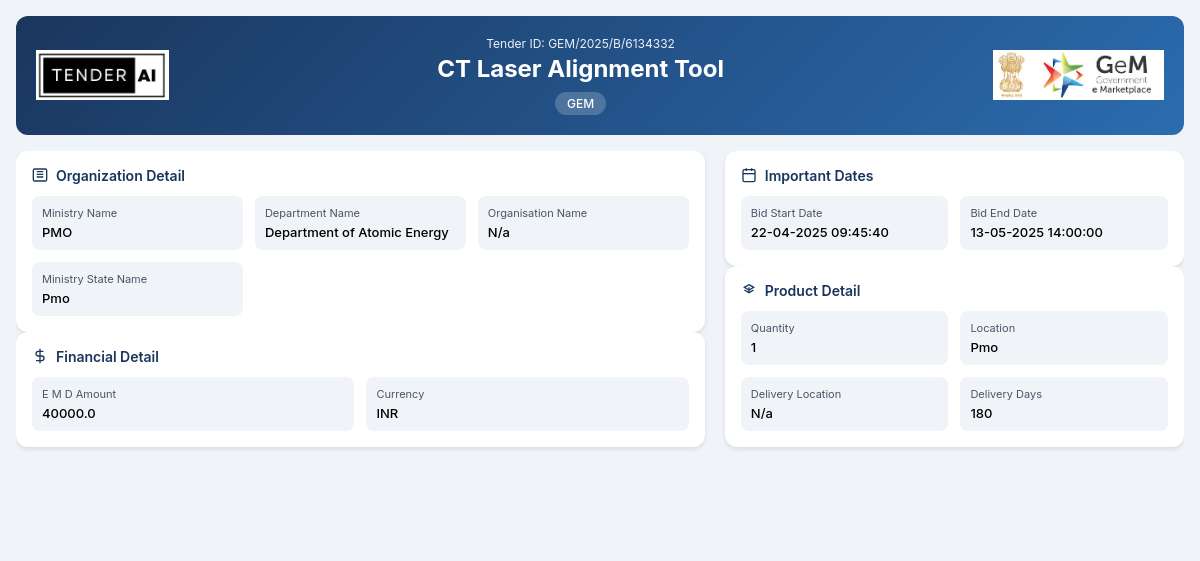

Department of Atomic Energy Tenders (GEM/2025/B/6134332)

CT Laser Alignment Tool

Tender Timeline

Tender Title: CT Laser Alignment Tool

Reference Number: GEM/2025/B/6134332

Issuing Authority: Department of Atomic Energy

The CT Laser Alignment Tool tender aims to procure advanced alignment tools essential for various applications in the nuclear and atomic energy sectors. The Department of Atomic Energy is seeking suppliers who can provide high-quality CT Laser Alignment Tools that meet specific technical and operational standards. The primary objectives of this tender include enhancing precision alignment capabilities, improving operational efficiency, and ensuring stringent safety and quality protocols throughout the procurement process.

Scope of Work and Objectives

The scope of work encompasses the supply of a CT Laser Alignment Tool, which is integral for precision alignment in complex setups typically found in atomic energy applications. The objectives include:

- Providing reliable and durable alignment tools suitable for industrial applications.

- Ensuring compliance with all safety regulations and quality standards specified by the Department of Atomic Energy.

- Completing the supply within the designated timeline and ensuring all delivered tools pass the necessary testing criteria.

Eligibility Criteria

Bidders must meet the following eligibility criteria to participate:

- Bidders should be registered entities with a proven track record in supplying similar equipment.

- Compliance with industry-standard operational practices is mandatory.

- Potential bidders must show evidence of prior experience in supplying to government or large-scale projects.

Technical Requirements

Eligible bidders are required to provide detailed specifications of their CT Laser Alignment Tool, which must include:

- Technical performance parameters meeting Department of Atomic Energy specifications.

- Quality certifications or compliance with relevant national and international standards.

- Any warranties or post-purchase support arrangements.

Financial Requirements

Financial stability must be demonstrated via:

- Submission of recent financial statements.

- Any necessary performance bonds or guarantees as stipulated in the tender documentation.

Document Submission Details

Bidders are required to submit the following documents:

- Completed tender forms.

- Proof of registration and necessary certifications.

- Technical and financial proposals in the specified formats as per submission guidelines.

Special Provisions

This tender includes provisions aimed at promoting participation from Micro, Small, and Medium Enterprises (MSEs) and startups. Eligible participants may benefit from reduced performance security requirements. Bidders are encouraged to refer to the detailed guidelines within the tender documentation to understand the full benefits available.

Evaluation Process

Bids will be evaluated based on:

- Technical compliance and specifications.

- Financial viability and cost-effectiveness.

- Historical performance of the bidding entity.

Delivery Locations

Suppliers are expected to deliver the alignment tools to designated sites specified by the Department of Atomic Energy which will be communicated at final award notification.

Contact Information

For inquiries regarding this tender, interested parties should refer to the official communication channels provided within the tender documents.

By adhering to these guidelines and preparing comprehensive tender submissions, bidders can effectively align their proposals with the Department of Atomic Energy's requirements. It is imperative that all submissions are completed as per the conditions laid out to ensure eligibility and evaluation for this critical procurement endeavor.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

3 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC)

- OEM Authorization Certificate

- Additional Doc 1 (Requested in ATC)

- Compliance of BoQ specification and supporting document *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity, demonstrating relevant experience in delivering comparable tools or solutions, and compliance with applicable industry regulations. Bidders must provide documentation to verify these qualifications, including registration certificates and proof of experience.

Bidders are required to submit a set of mandatory certificates, which may include quality assurance certifications such as ISO or equivalent, compliance certificates that align with industry standards, and technical specifications documents that validate the performance of the CT Laser Alignment Tool.

The registration process involves submitting a formal tender application along with necessary documentation that proves eligibility. Bidders should follow the instructions outlined in the tender documentation, ensuring all forms are completed and submitted in the accepted document formats.

The Earnest Money Deposit (EMD) is a financial guarantee submitted by bidders to secure their participation in the bidding process, typically ranging from a specific percentage of the bid value. Additionally, a performance security may be required upon contract award, which ensures compliance with the terms of the tender.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders