Tender Title: Mechanical Seal Tender

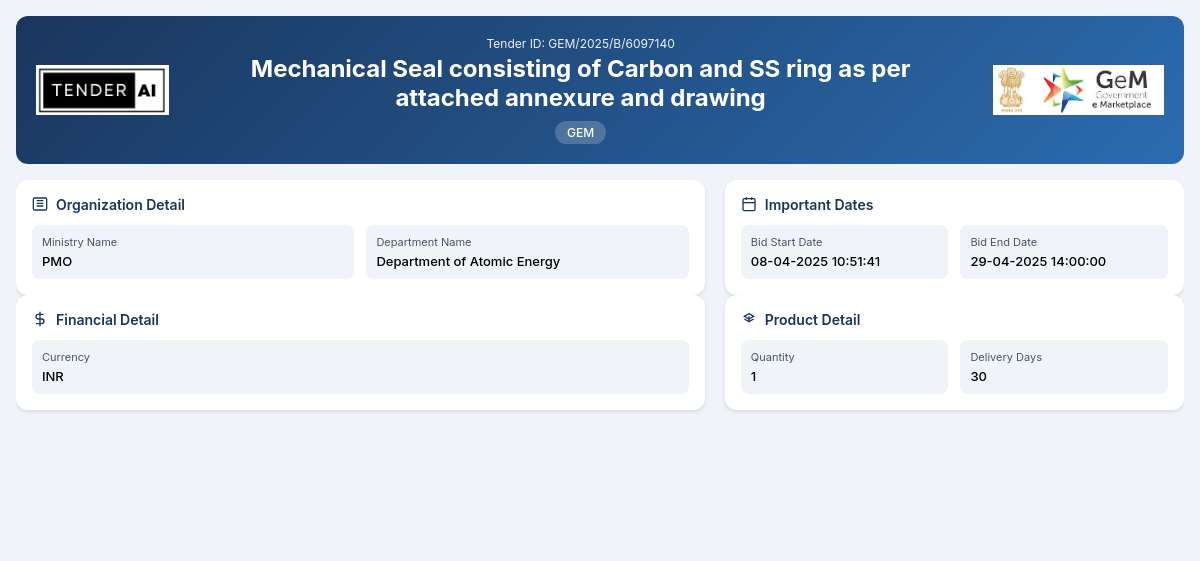

Tender Reference Number: GEM/2025/B/6097140

Issuing Authority/Department: Department of Atomic Energy

The Mechanical Seal Tender invites bids for the procurement of high-quality mechanical seals consisting of carbon and stainless steel rings. This requirement is outlined in an annexure and detailed drawing provided within the documentation. The scope of work encompasses the production, supply, and delivery of 40 units of mechanical seals that meet the specified design and material criteria, ensuring durability and reliability in performance.

Scope of Work and Objectives

The primary objective of this tender is to facilitate the acquisition of mechanical seals which are crucial for various applications within the energy sector. Bidders are expected to deliver products that adhere strictly to the technical specifications provided, ensuring compliance with industry standards.

Eligibility Criteria

Eligible bidders must be registered entities in the relevant industry, holding the necessary licenses and certifications to supply mechanical products. Companies are encouraged to demonstrate their experience in manufacturing or supplying mechanical seals, particularly those that meet the specified requirements.

Technical Requirements

Bids must detail the technical specifications of the mechanical seals, including, but not limited to, dimensions, materials used (carbon and stainless steel), resistance to environmental factors, and any compliance with industry quality standards. The technical proposal should include supporting documentation to affirm adherence to the specifications laid out in the annexure.

Financial Requirements

Bidders must provide a comprehensive financial proposal, which includes pricing details per unit, total cost for the 40 units required, and any additional costs, such as shipping or handling. The proposal must also reflect the bidder's understanding of the market rates for such seals.

Document Submission Details

Interested bidders are required to submit their proposals through the prescribed channels. All documentation should be clearly labeled with the tender reference number. It is crucial to ensure all submissions are completed on or before the stipulated deadline to be considered for evaluation.

Special Provisions

This tender encourages participation from Micro, Small, and Medium Enterprises (MSEs). Eligible MSEs may benefit from relaxed criteria to foster inclusiveness in the bidding process. Startups are also welcomed, provided they can demonstrate the capability and technical expertise required to fulfill the contract.

Evaluation Process

The evaluation of bids will be conducted based on predetermined criteria, including technical compliance, financial viability, and past performance. Bidders must ensure that their submissions are complete to facilitate a smooth evaluation process.

Delivery Locations

Successful bidders will be required to deliver the mechanical seals to designated locations specified in the final agreement. Delivery terms will be formally discussed upon awarding of the contract.

Contact Information

For additional details or inquiries related to this tender, participants may refer to the official contact channels provided within the tender documentation. It is encouraged for bidders to clarify any uncertainties prior to submission to ensure compliance with the requirements.

In conclusion, this tender for mechanical seals represents a significant opportunity for suppliers in the industry to showcase their capacities and contribute to an essential operational area within the energy sector.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

4 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC)

- OEM Authorization Certificate

- Additional Doc 1 (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity with proper licenses to manufacture or supply mechanical seals. Bidders must demonstrate relevant experience in their proposals and comply with technical specifications set forth in the tender documentation.

Bidders must ensure that their products meet the specified technical specifications, which include the use of appropriate materials such as carbon and stainless steel, compliance with industry standards, and dimensions detailed in the annexure. Supporting documentation should be provided for assessment.

The payment terms will be agreed upon post-bid acceptance, which typically involves an upfront payment followed by milestone payments upon delivery. Bidders may also be required to submit a performance security deposit to guarantee contract fulfillment, the specifics of which will be outlined in the final agreement.

Documents for the mechanical seal tender must be submitted electronically through the designated portal. All files should be in specified formats and adequately labeled with the tender reference number to ensure proper processing of the bids.

Yes, the tender includes provisions aimed at benefiting Micro, Small, and Medium Enterprises (MSEs), such as relaxed qualification criteria and potential financial incentives. This initiative encourages broader participation and support through governmental policies aimed at fostering local industries.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders