Tender Title: Main Steam Stop Valve Stem with Box Nut

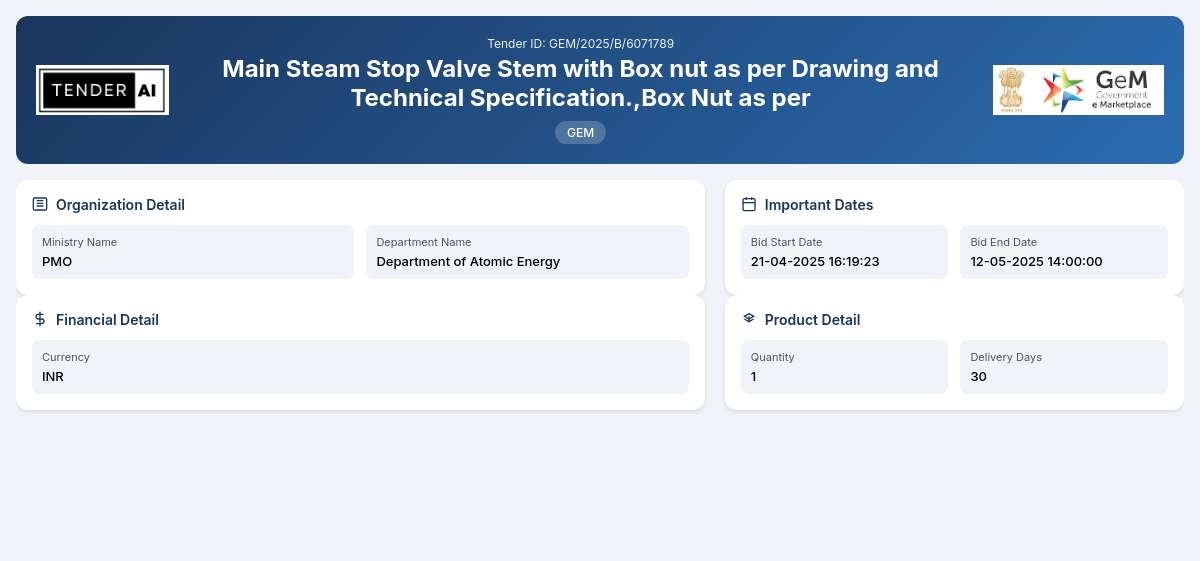

Tender Reference Number: GEM/2025/B/6071789

Issuing Authority: Department of Atomic Energy

The Main Steam Stop Valve Stem with Box Nut tender invites suppliers to provide specialized components that adhere to the stringent specifications set forth in the accompanying technical documents. This tender aims to procure several units that are crucial for the functionality and safety of steam control systems in nuclear facilities.

Scope of Work and Objectives

The primary objective of this tender is to secure Main Steam Stop Valve Stems along with Box Nuts as per the detailed drawings and technical specifications provided. Suppliers are expected to deliver a total of 6 units that meet rigorous quality and safety standards, ensuring they are suitable for application in high-pressure environments. The successful bidders will demonstrate their capacity to fulfill these requirements within the specified framework.

Eligibility Criteria

To be eligible for participation in this tender, bidders must be registered entities with relevant operational capabilities. This includes having experience in manufacturing or supplying valve components that comply with applicable industry standards. It is imperative that all bids are submitted by qualified suppliers who can substantiate their eligibility through appropriate documentation.

Technical Requirements

Bid submissions must include thorough documentation showing compliance with the detailed technical specifications. Each bidder should provide evidence of adherence to IS-28-1985 standards pertaining to the fabrication and quality testing of these components. The submitted products will undergo rigorous evaluation to ensure they meet the predetermined technical standards essential for operational reliability.

Financial Requirements

While specific financial details are not outlined in this document, bidders are reminded to provide competitive pricing reflecting the quality of their offerings. Compliance with any budgetary limitations set forth by the contracting authority will be assessed during the evaluation process. Suppliers must also secure the necessary cost assurance guarantees.

Document Submission Details

All proposals must be submitted electronically in a specified format as clarified in the subsequent guidelines. Bidders are encouraged to ensure that all documentation is complete, as incomplete submissions may not be considered.

Special Provisions

This tender may include provisions for Micro, Small, and Medium Enterprises (MSEs) and startups, fostering an inclusive procurement environment that encourages participation from diverse business entities.

Evaluation Process

Every submission will be evaluated based on pre-defined criteria including compliance with technical specifications, pricing, and the bidder's overall qualifications. The evaluation will prioritize proposals that not only meet the requirements but also demonstrate value and reliability.

Delivery Locations

The successful bidder is expected to deliver the accepted goods directly to the relevant facilities outlined in the tender specifications. Specific delivery locations will be communicated to the selected vendor once the bids are awarded.

Contact Information

For any inquiries, interested parties are encouraged to reach out to the administering department through specified contact channels available in the tender documentation. Please ensure all communications are directed appropriately.

This tender represents a critical opportunity for suppliers in the valve manufacturing sector. Bidders are urged to prepare their proposals diligently and ensure they meet all stipulated requirements.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

5 DocumentsSimilar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity with a proven track record in manufacturing or supplying components that comply with specified technical standards. Bidders must provide adequate documentation to demonstrate their operational capabilities and experience relevant to the Main Steam Stop Valve Stem and Box Nut specifications mentioned in the tender. Additionally, adherence to industry safety and quality standards is paramount.

Products must adhere to the technical specifications outlined in the tender documents, specifically following IS-28-1985 standards. This includes demonstrating compliance with manufacturing processes and quality testing protocols applicable to high-pressure valve components. Detailed drawings and technical documents will guide bidders in meeting these critical specifications.

Bidders are required to submit competitive pricing that reflects the quality of their products. Although specific financial terms are not detailed in this document, all bids must align with budgetary considerations and demonstrate cost-effectiveness while ensuring compliance with the high-quality standards expected from commissioned suppliers.

All documents must be submitted electronically in the prescribed format outlined in the tender guidelines. Bidders are encouraged to ensure complete submissions as any lack of necessary documentation may lead to disqualification. Detailed instructions for submission formats are provided within the tender documentation.

MSEs may benefit from specific provisions integrated into the tender process, designed to enhance their participation in public procurement. The tender may prioritize MSEs for consideration, encouraging their growth and ensuring that diverse business entities are represented in the bidding process. Compliance with local content policies and ‘Make in India’ principles could also provide additional advantages.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders