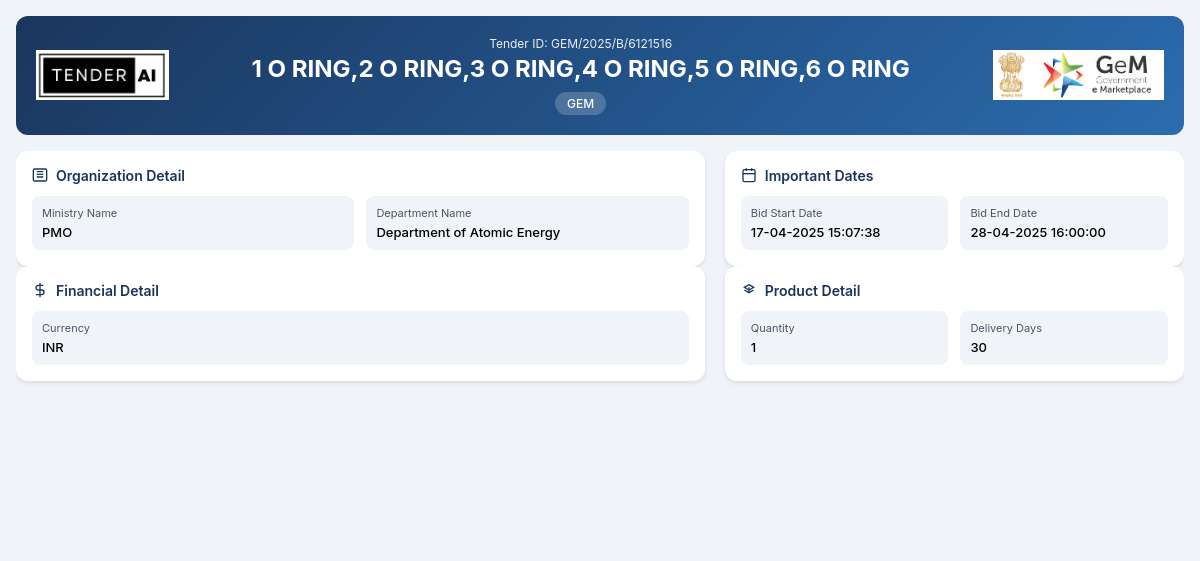

Department of Atomic Energy Tender by Nuclear Power Corporation Of India Limited (GEM/2025/B/6121516)

1 O RING,2 O RING,3 O RING,4 O RING,5 O RING,6 O RING

Tender Timeline

Tender Title: VAKO MAKE SEAL O RINGS

Reference Number: GEM/2025/B/6121516

Issuing Authority/Department: Department of Atomic Energy

The Department of Atomic Energy is pleased to announce a tender for VAKO MAKE SEAL O RINGS under the reference number GEM/2025/B/6121516. This tender is designed to procure a total of 64 units of various O rings, categorized as 1 O RING, 2 O RING, 3 O RING, 4 O RING, 5 O RING, and 6 O RING. The scope of this tender encompasses the supply of high-quality O rings that meet the stringent technical and quality specifications required by the department.

Scope of Work and Objectives

The primary objective of this tender is to locate reliable suppliers capable of providing VAKO MAKE SEAL O RINGS that satisfy the technical and operational requirements determined by the Department of Atomic Energy. Suppliers are expected to deliver all completed units within the specified timeline to ensure continuity in departmental operations.

Eligibility Criteria

Suppliers intending to bid must meet the established eligibility criteria, which typically include being a registered entity under applicable laws, possessing relevant technical capacity, and having prior experience in the supply of O rings or similar products.

Technical Requirements

Bidders must provide O rings that strictly conform to the specified technical requirements detailed in the tender documents. This includes adherence to relevant quality standards and specifications, ensuring that the materials are suitable for use in high-performance applications characteristic of the department’s needs.

Financial Requirements

Suppliers are required to include their pricing information in the bid submission, taking into account all potential costs involved in the production and delivery of the O rings. Financial documents must demonstrate the vendor’s capacity to fulfill the order in a timely and efficient manner, showcasing a sustainable business model.

Document Submission Details

All bids must be submitted electronically through the designated e-procurement platform. Accurate completion of required forms and timely submission is essential for consideration. Bidders should consult the detailed submission guidelines in the tender documentation to ensure compliance.

Special Provisions

This tender may include benefits aimed at Micro, Small, and Medium Enterprises (MSEs) and provisions to support the initiatives for startups. Such measures will encourage participation from diverse sources, fostering innovation and competition.

Evaluation Process

The evaluation process will follow a systematic approach, assessing each bid based on predetermined criteria, including technical compliance, financial viability, and supplier experience. Specific evaluation metrics will be provided in the tender documents.

Delivery Locations

Successful bidders will be expected to deliver the O rings to specified locations as outlined in the tender’s documentation. Timely delivery is crucial, and bidders should account for this in their submission proposal.

Contact Information

For inquiries or further clarifications regarding the tender, interested parties should refer to the contact details provided in the tender document. It is advisable to communicate through the official channels to ensure accurate information exchange.

This tender represents a significant opportunity for qualified suppliers to engage with the Department of Atomic Energy. Participants must ensure that they understand all aspects of the bidding process and comply with the tender requirements for a successful bid submission.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

5 DocumentsDocuments Required from Seller

- Additional Doc 1 (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements for participants include being a legally registered entity, demonstrating prior experience in the supply of O rings or similar components, and showcasing the necessary technical capabilities to fulfill the order. Suppliers must provide relevant documentation to substantiate their qualifications.

Bidders must include specific required certificates that demonstrate compliance with local and international quality standards. This may involve quality assurance certifications, safety compliance documents, and any other necessary certifications pertinent to the manufacturing and supply of O rings.

The registration process involves creating an account on the e-procurement platform designated for this tender. Suppliers should follow the outlined procedures on the platform to ensure that their submissions are valid. Detailed steps for registration can be found in the tender’s documentation.

All accepted document formats for submission must be specified in the tender documentation. Commonly accepted formats typically include PDF and Word documents, but bidders are encouraged to verify exact requirements in the tender notice to avoid disqualification.

Payment terms are usually defined in the tender documentation and may include provisions for upfront payments, milestone payments based on delivery schedules, or upon successful completion of quality checks. Bidders must ensure they are familiar with these terms to price their bids accurately.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders