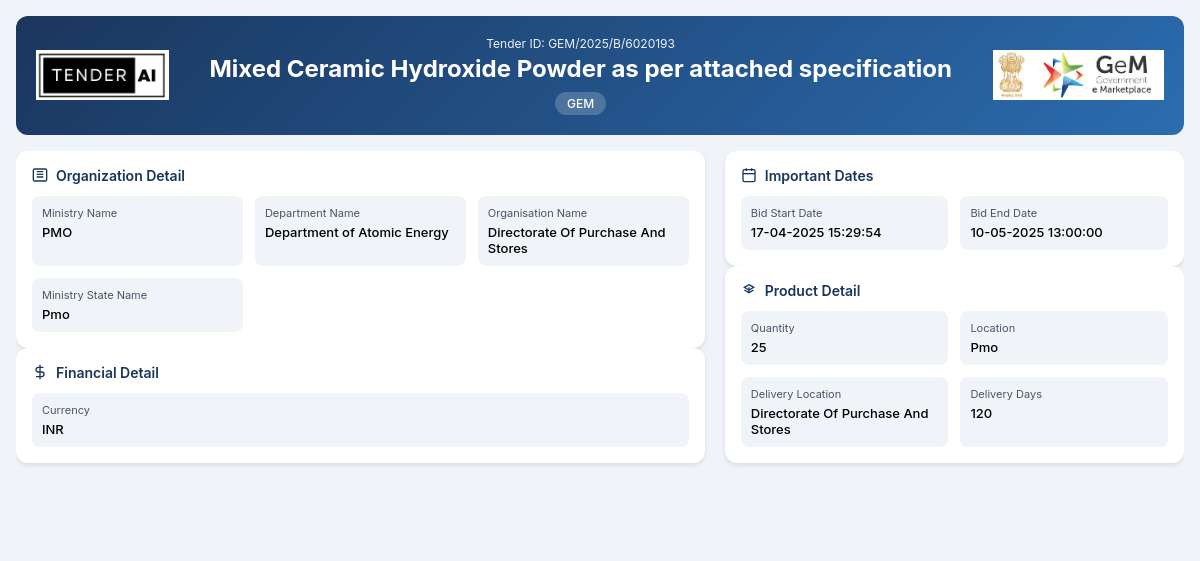

Department of Atomic Energy Tender by Directorate Of Purchase And Stores (GEM/2025/B/6020193)

Mixed Ceramic Hydroxide Powder as per attached specification

Tender Timeline

Tender Title: Mixed Ceramic Hydroxide Powder

Tender Reference Number: GEM/2025/B/6020193

Issuing Authority: Department of Atomic Energy

Scope of Work and Objectives

The objective of this tender is to procure Mixed Ceramic Hydroxide Powder as per the specifications detailed in the attached documentation. This high-quality material is essential for various applications within the atomic energy sector. The Department aims to source 25 units of this product to meet operational requirements efficiently.

Eligibility Criteria

To qualify for this tender, bidders must be recognized and registered entities capable of supplying the specified material. They must demonstrate compliance with the technical and financial requirements set forth in the tender documents. It is imperative for bidders to have the capacity to deliver the required quantity within the defined timelines.

Technical Requirements

Bidders must provide a detailed technical proposal that meets the specifications for Mixed Ceramic Hydroxide Powder. This includes details on the composition, manufacturing process, and quality control measures. Adherence to applicable quality standards and performance metrics is essential.

Financial Requirements

Bidders should include a comprehensive financial proposal outlining the cost per unit and any additional charges. The strategies for pricing should reflect competitive market rates while maintaining quality standards. Bidders must also understand the financial obligations including Earnest Money Deposit (EMD) and performance security.

Document Submission Details

All bids must be submitted in the specified format and include all mandatory documentation. Bidders are advised to carefully review the submission guidelines to ensure their bids meet each requirement. Submissions can be made electronically or in hard copy, depending on the instructions detailed in the tender documentation.

Special Provisions

Bidders qualifying as Micro, Small, and Medium Enterprises (MSEs) or as startups may benefit from preferential treatment during the evaluation process. This includes potential price relaxation and separate quotas that aim to promote local entrepreneurship.

Evaluation Process

The evaluation of submitted tenders will be carried out based on the established criteria outlined in the documentation. Aspects such as technical compliance, pricing, and delivery capabilities will be considered. The evaluation process aims to ensure transparency and fairness in awarding the contract.

Delivery Locations

Delivery of the Mixed Ceramic Hydroxide Powder will be required at specified locations as detailed in the tender documentation, which are anticipated to align with the operational needs of the Department of Atomic Energy.

Contact Information

For any inquiries regarding this tender, please refer to the official channels provided in the tender documentation. It is crucial for bidders to ensure that they reach out for clarification on any aspect of the tender to avoid discrepancies in their submissions.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

4 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The qualification requirements include being a registered entity capable of supplying the specified Mixed Ceramic Hydroxide Powder. Bidders must demonstrate compliance with technical and financial stipulations outlined in the tender. It is also mandatory to showcase prior experience or capacity in similar projects, ensuring availability and reliability in meeting delivery timelines.

Bidders need to submit a detailed registration document that includes proof of registration as a business entity, including applicable licenses and certifications relevant to the supply of chemical substances. Additionally, financial statements, an EMD, and any specific performance certificates may also be required to validate the capacity to fulfill the tender obligations.

The accepted document formats generally include PDF, Word, and Excel files. It is crucial that all submitted documents are clear and legible, as this will be considered during the evaluation process. Bidders should also adhere to any specific formatting guidelines indicated in the tender to ensure compliance and avoid disqualification.

Payment terms are typically outlined in the tender documentation, specifying when payments will be processed upon completion of delivery and acceptance of the Mixed Ceramic Hydroxide Powder. A performance security might also be required, aimed at guaranteeing that bidders fulfill their commitments as per the contract terms. This security is usually a percentage of the contract value and is retained until satisfactory completion.

MSEs may have specific provisions under the tender, allowing for preferential pricing and enhanced evaluation criteria. This includes potential price relaxation and support in terms of fewer compliance requirements. Additionally, compliance with ‘Make in India’ policies may present local sourcing opportunities that further benefit MSEs in procurement dynamics.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders