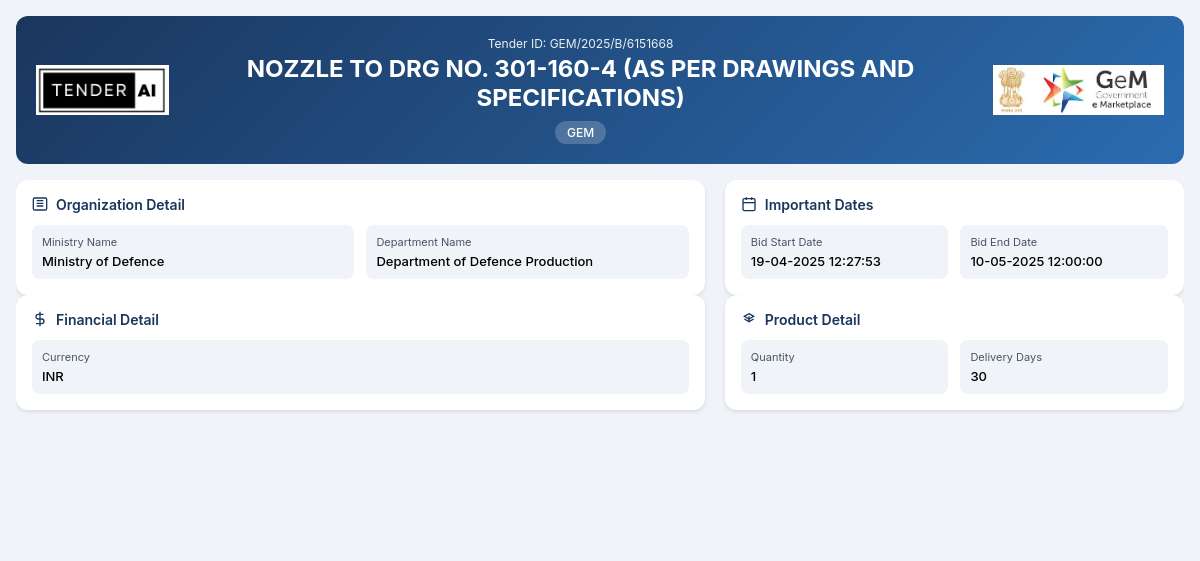

Department of Defence Production Tender by Armoured Vehicles Nigam Limited (GEM/2025/B/6151668)

NOZZLE TO DRG NO. 301-160-4 (AS PER DRAWINGS AND SPECIFICATIONS)

Tender Timeline

Tender Title: NOZZLE TO DRG NO. 301-160-4

Reference Number: GEM/2025/B/6151668

Issuing Authority:

Ministry of Defence - Department of Defence Production

The NOZZLE TO DRG NO. 301-160-4 tender is a pivotal opportunity for suppliers interested in providing components that meet specified design requirements outlined in the tender specifications. With a total quantity requested of 2924 units, the objective is to procure high-quality nozzle components that adhere strictly to engineering drawings and specifications provided therein.

Scope of Work and Objectives

The primary objective of this tender is to procure nozzles as per the drawing specifications (i.e., DRG NO. 301-160-4). Suppliers are expected to meet the technical specifications while ensuring compliance with the quality standards set forth by the Ministry of Defence. The successful bidder should demonstrate capability in manufacturing and delivering nozzles that fulfill both operational and quality requirements outlined in the tender.

Eligibility Criteria

To qualify for this tender, bidders must:

- Be a registered entity operating under Indian law.

- Demonstrate prior experience in manufacturing similar items.

- Have a robust quality assurance system in place.

- Adhere to all local and national supply chain regulations.

Technical Requirements

Bidders must ensure that the nozzles produced comply with the specific technical specifications and standards mandated in the tender documents. This includes adherence to the prescribed materials, dimensions, and performance characteristics as indicated in the engineering drawings.

Financial Requirements

All bidders are required to present their financial credentials, including:

- Submission of an earnest money deposit (EMD) in the prescribed format.

- Evidence of financial stability and operational capability to meet the tender requirements.

- A competitive pricing proposal that is economically viable while maintaining quality.

Document Submission Details

Interested suppliers must ensure that all required documents including technical specifications, financial proposals, and eligibility proofs are submitted in the specified format. Submission methods and details will be clarified in the complete tender documentation.

Special Provisions

This tender aligns with initiatives to support Micro, Small, and Medium Enterprises (MSEs) and startups. Preference may be given in the evaluation process to bids that demonstrate compliance with national policies fostering domestic manufacturing.

Evaluation Process

Bids will be evaluated based on criteria encompassing technical specifications, quality compliance, pricing proposals, and capacity to deliver. Each submission will go through a detailed review process to ensure alignment with the tender requirements before award.

Delivery Locations

The delivery locations for the nozzles will be specified within the final tender notice. All bidders must consider logistics and delivery capabilities in their proposals.

Contact Information

For further inquiries and clarifications, interested parties may refer to the official contact details provided in the complete tender documentation. Please ensure all communication regarding this tender is conducted through the prescribed channels to avoid discrepancies.

In conclusion, the NOZZLE TO DRG NO. 301-160-4 tender has been designed to encourage high-quality submissions that meet the technical and operational needs of the Ministry of Defence, thus upholding the standards required for national defense operations.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

4 DocumentsSimilar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity under Indian law, demonstrating prior experience in manufacturing similar items, and having a robust quality assurance system. It is essential for bidders to adhere to both local and national supply chain regulations to qualify for the tender.

Suppliers must ensure that the nozzles produced comply with the technical specifications provided in the engineering drawings. This includes dimensions, materials, and performance characteristics as mandated by the Ministry of Defence documentation to ensure functionality and reliability.

Yes, bidders must present their financial credentials clearly, which includes submitting an earnest money deposit (EMD) in the prescribed format and evidence of financial stability. Participants should provide a competitive pricing proposal that maintains the quality standards expected by the Ministry of Defence.

All required documents including technical specifications and financial proposals must be submitted in the specified formats outlined in the tender documentation. It is essential to follow the prescribed submission methods to ensure compliance and consideration during evaluation.

This tender includes special provisions for MSEs, supporting national initiatives to encourage domestic manufacturing. Bids from MSEs may receive preferential consideration during evaluation, promoting their growth and involvement in government procurement processes.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders