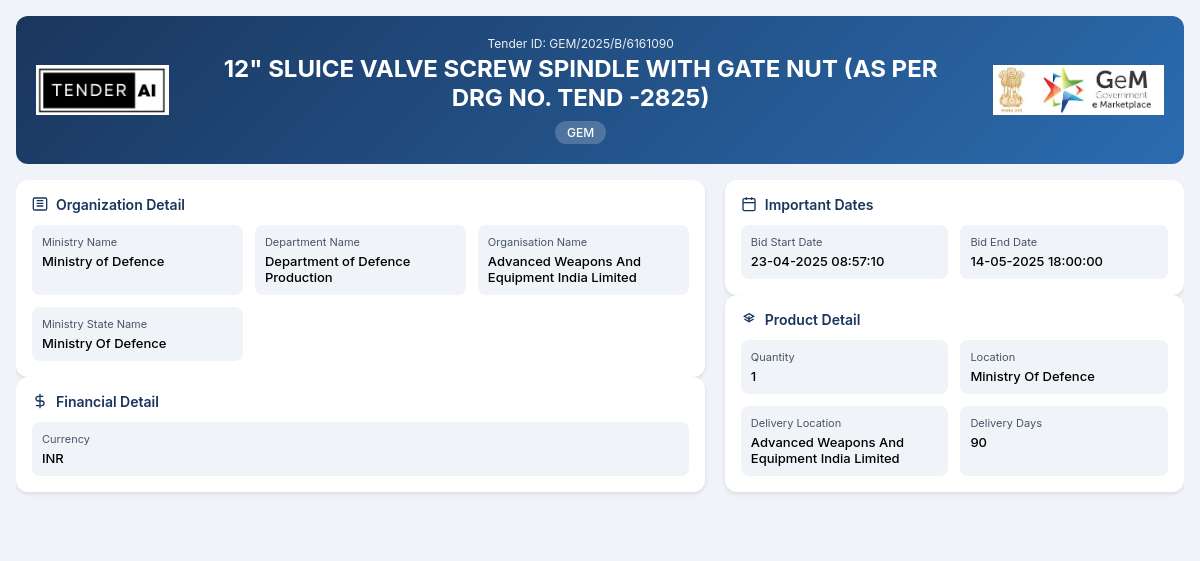

Department of Defence Production Tender by Advanced Weapons And Equipment India Limited (GEM/2025/B/6161090)

12" SLUICE VALVE SCREW SPINDLE WITH GATE NUT (AS PER DRG NO. TEND -2825)

Tender Timeline

Tender Title: 12" Sluice Valve Screw Spindle with Gate Nut (As Per Drg No. TEND -2825)

Tender Reference Number: GEM/2025/B/6161090

Issuing Authority/Department: Department of Defence Production, Ministry of Defence

The tender invites proposals for the supply of a 12” Sluice Valve Screw Spindle with Gate Nut in accordance with the specified design drawing TEND -2825. With an emphasis on quality and compliance with industry standards, this tender seeks to engage suppliers who can demonstrate technical proficiency and reliable delivery capabilities.

Scope of Work and Objectives

The primary objective of this tender is to procure a Sluice Valve Screw Spindle that meets the technical specifications and quality standards required by the Department of Defence Production. The successful bidder will be responsible for delivering the specified quantity as per the conditions outlined in the tender documents.

Eligibility Criteria

- Registered Entity: Bidders should be duly registered and authorized to operate in the relevant industry.

- Technical Capability: Proposals must demonstrate the capacity to manufacture and deliver the specified items in line with governmental quality standards.

- Compliance History: Bidders should provide evidence of past compliance with similar tenders, showcasing their reliability and performance record.

Technical Requirements

Bidders must adhere to the following technical specifications for the item:

- List details in line with the drawing TEND -2825

- Material specifications and any applicable industry standards should be highlighted in the proposals.

Financial Requirements

Bidders are required to provide detailed costing information, including a breakdown of all associated costs with the supply of the Sluice Valve Screw Spindle. Proposals should comply with the budget allocation as determined by the Ministry of Defence.

Document Submission Details

Bidders must provide the necessary documentation, including:

- Company registration certificate

- Technical documentation verifying compliance with the technical specifications

- Compliance with financial requirements outlined in the tender.

Special Provisions

The tender encourages proposals from Micro, Small, and Medium Enterprises (MSEs) and shall consider special provisions for starting businesses as part of the evaluation process.

Evaluation Process

The evaluation of bids will be conducted based on:

- Compliance with technical specifications

- Financial viability

- Delivery timelines proposed by bidders

- Previous performance in similar contracts

Delivery Locations

The delivery will be executed as per the instructions provided by the Department of Defence Production, with specific locations to be confirmed upon contract award.

Contact Information

For any inquiries related to the tender, bidders are encouraged to reach out to the contact listed in the official tender documents.

This tender represents a significant opportunity for suppliers specializing in industrial valve components to engage with the government, ultimately contributing to vital infrastructure projects and defense initiatives.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

6 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC)

- Additional Doc 1 (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity with appropriate approvals and licenses to operate in the relevant industry. Bidders must demonstrate their technical capabilities to manufacture the 12” Sluice Valve Screw Spindle as per the drawing specifications and provide evidence of prior compliance with similar contracts.

Bidders must include a valid company registration certificate, tax clearance certificate, and any industry-relevant certification that demonstrates compliance with the technical requirements. Documentation substantiating adherence to quality standards is also vital.

Participation requires a registration process that involves submitting the required documents to the appropriate government tender platform. Bidders must ensure they comply with all regulations and submit proposals in the accepted document formats specified in the tender guidelines.

Financial proposals must provide a complete breakdown of the costs associated with the supply of the Sluice Valve Screw Spindle, including item unit costs, taxes, shipping, and other charges. The financial proposal should be structured clearly to facilitate an efficient evaluation process.

Bids will be evaluated based on compliance with the technical specifications, the financial proposal submitted, delivery timelines proposed, and the bidder’s performance history in similar contracts. The assessment will prioritize bidders who meet or exceed all requirements established in the tender documents.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders