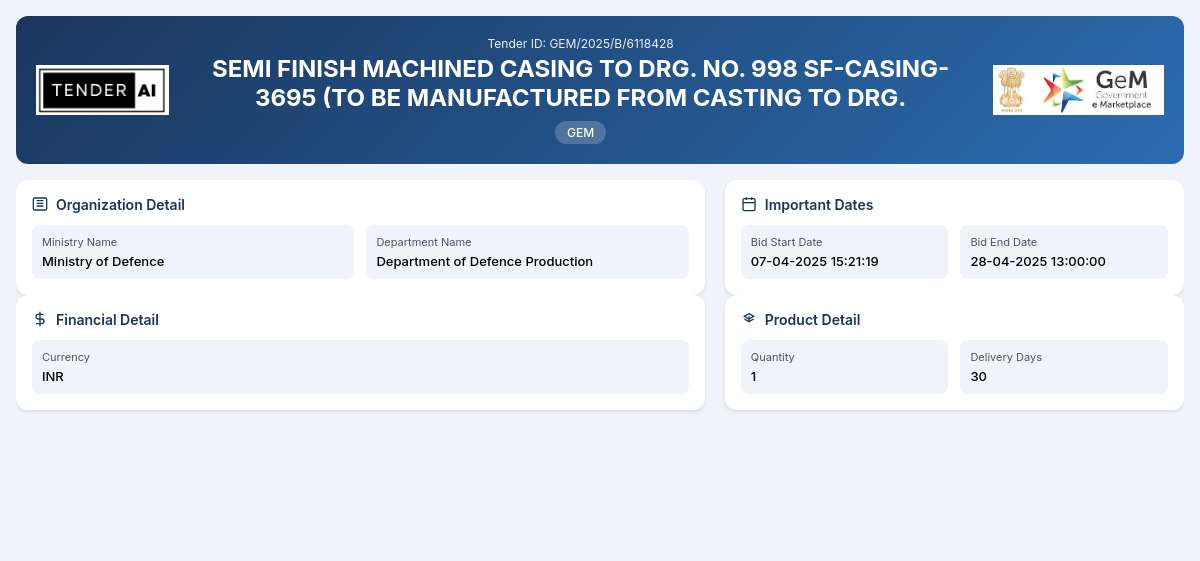

Department of Defence Production Tender by Armoured Vehicles Nigam Limited (GEM/2025/B/6118428)

SEMI FINISH MACHINED CASING TO DRG. NO. 998 SF-CASING-3695 (TO BE MANUFACTURED FROM CASTING TO DRG.

Tender Timeline

Tender Title: Semi Finish Machined Casing

Reference Number: GEM/2025/B/6118428

Issuing Authority

This tender is issued by the Department of Defence Production, under the auspices of the Ministry of Defence.

Scope of Work and Objectives

The primary objective of this tender is to invite bids for the supply of semi finish machined casting, specifically adhering to the design and quality specifications detailed in Drawing No. 998 SF-Casing-3695. The successful bidder will be required to manufacture these components from the provided casting to the exact specifications laid out to ensure that they meet the operational needs of defense applications. The total quantity required for this tender is 325 units.

Eligibility Criteria

To participate in this tender, bidders must meet specific eligibility criteria, which typically include being a registered entity capable of fulfilling the requirements stated in this tender.

Technical Requirements

Bidders are expected to comply with all technical requirements as provided in the drawing and specifications. This includes adherence to defined machining practices, quality control standards, and material specifications. Bidders should demonstrate their capability in manufacturing components of similar complexity and provide relevant experience documentation.

Financial Requirements

Bidders must demonstrate financial stability and capacity to undertake the production of the required units. This may involve submitting financial statements or bank guarantees as proof of ability to perform under the tender's provisions.

Document Submission Details

All bid submissions must be made in accordance with the outlined submission requirements, which will stipulate the acceptable formats and documentation necessary to support the bid. This includes the completion of all required forms and inclusion of necessary certificates.

Special Provisions

Provisions may exist for Micro, Small, and Medium Enterprises (MSEs) which could allow for certain benefits in the bidding process. Bidders are encouraged to inquire about any special provisions that may apply to promote inclusivity within the procurement process.

Evaluation Process

The evaluation process for this tender will follow a structured approach, assessing bids based on criteria that include technical compliance, financial stability, and previous experience in similar contracts. Detailed evaluation guidelines will be issued with the tender documents.

Delivery Locations

The specific delivery locations for the finished products will be determined in accordance with the stipulations within the tender documentation. Bidders should be aware of logistics and transportation requirements tied to the delivery of these items.

Contact Information

For inquiries and further clarification regarding this tender, bidders may contact the issuing team at the Department of Defence Production. Contact details should be referenced appropriately in the documentation provided.

This tender represents a critical opportunity for qualified suppliers to engage with national defense production, thereby ensuring their contributions play a vital role in bolstering defense capabilities.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

6 DocumentsDocuments Required from Seller

- Bidder Turnover

- Certificate (Requested in ATC)

- Additional Doc 1 (Requested in ATC)

- Additional Doc 2 (Requested in ATC)

- Additional Doc 3 (Requested in ATC)

- Additional Doc 4 (Requested in ATC)

- Compliance of BoQ specification and supporting document *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a legally registered entity that possesses the manufacturing and financial capabilities to undertake the production of semi-finish machined casing. Potential bidders must show evidence of previous experience in similar work, adhering to the quality standards specified in the tender document. Compliance with all technical specifications outlined in Drawing No. 998 SF-Casing-3695 is also essential to ensure that the products meet operational standards.

Bidders are typically required to submit various certificates including business registration papers, quality assurance certifications (such as ISO certifications), and financial documents that demonstrate the company’s stability. It is crucial to include all relevant documents in the required format to validate the bid and ensure compliance with tender requirements.

The Earnest Money Deposit (EMD) is typically required to demonstrate the bid’s seriousness and must be submitted along with the tender. The amount for the EMD will be specified in the tender documents and will vary based on the total bid value. Participants must ensure that the EMD is paid in the prescribed format to avoid disqualification.

The evaluation and selection process includes a detailed review of each bid based on compliance with technical requirements, pricing, and overall capability to deliver. Bids will be assessed not only on cost but also on qualitative factors such as delivery timeframes and bidder experience. The results of this evaluation will be communicated to all bidders once the process is complete.

Yes, there are often specific benefits for Micro, Small, and Medium Enterprises (MSEs) and startups in government tenders. These may include financial assistance, reduced EMD requirements, or favorable evaluation criteria. Applicants are encouraged to seek information on how these benefits can aid in their bid preparation and submission process. Compliance with ‘Make in India’ initiatives promoting local content in procurement is also a considerable factor in the evaluation.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders