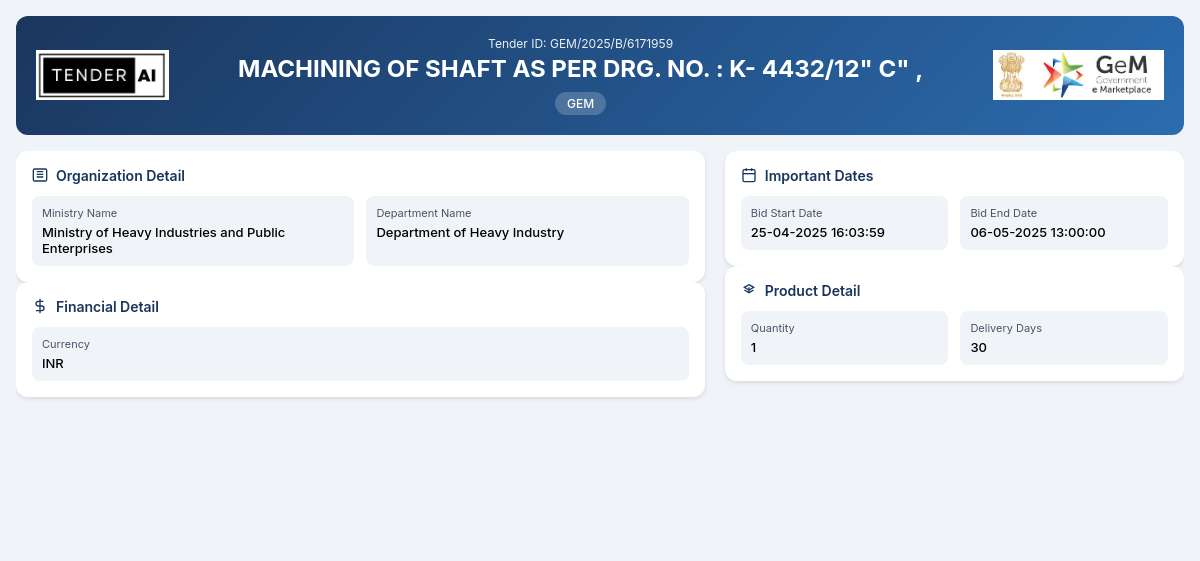

Department of Heavy Industry Tender by Andrew Yule And Company Limited (GEM/2025/B/6171959)

MACHINING OF SHAFT AS PER DRG. NO. : K- 4432/12" C" ,

Tender Timeline

Tender Title: Machining of Shaft as per DRG. No.: K-4432/12"C"

Tender Reference Number: GEM/2025/B/6171959

Issuing Authority/Department: Department of Heavy Industry, Ministry of Heavy Industries and Public Enterprises

The Machining of Shaft tender involves the precise machining of a shaft which is essential for various industrial applications. The selected contractor will be expected to follow stringent technical specifications outlined in the provided drawing, DRG. No.: K-4432/12"C". The main objective of this tender is to ensure high-quality finished products that meet the operational needs of the Department of Heavy Industry.

Scope of Work and Objectives

The successful completion of this tender encompasses the following key responsibilities:

- Accurately machining the shaft as per the specifications provided in the accompanying drawing.

- Ensuring that all completed work complies with the highest industry standards for quality and safety.

- Delivering the finished product within the stipulated timeframe, guaranteeing minimal disruption to production schedules.

Eligibility Criteria

To participate in this tender, bidders must meet specific eligibility criteria, which generally include:

- Registration as a legal entity in accordance with national regulations.

- Proven track record in machining and manufacturing similar components.

- Compliance with the relevant safety and quality standards.

Technical Requirements

The technical specifications for the shaft machining work involve:

- Adhering strictly to the dimensions and tolerances provided in DRG. No.: K-4432/12"C".

- Utilization of modern machining technologies and tools to ensure precision.

- Conducting necessary quality checks and inspections throughout the machining process.

Financial Requirements

Bidders will be required to demonstrate financial stability, including:

- Submission of financial statements from the past two years.

- A valid certificate of tax compliance.

- Evidence of adequate financial backing to support the project execution.

Document Submission Details

Bidders must submit all required documents electronically through the specified government procurement portal. The necessary documentation includes:

- Technical proposal detailing the methodology and compliance with specifications.

- Financial proposal outlining estimated costs.

- Certificates and compliance documents as described in the eligibility section.

Special Provisions

This tender includes special provisions for Micro, Small, and Medium Enterprises (MSEs) and startups. Eligibility for such provisions provides opportunities for MSEs to participate competitively.

Evaluation Process

A transparent evaluation process will be followed to assess the tenders based on:

- Compliance with technical specifications.

- Financial viability and pricing proposals.

- Past performance records and references from similar projects.

Delivery Locations

The finished shafts must be delivered to designated locations specified by the Department of Heavy Industry.

Contact Information

For any queries, specific contacts may be reached through the official channels of the Department of Heavy Industry. Detailed contact information is expected to be made available in official communications.

This tender aims to enhance local manufacturing capabilities through skilled machining of essential components while encouraging participation from MSEs to stimulate economic growth in the sector.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

4 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity compliant with national regulations, having a proven track record in similar machining projects, and meeting quality and safety standards set forth in the tender documentation.

Bidders must provide valid certificates demonstrating tax compliance, along with any industry-specific credentials that validate their capabilities in machining, ensuring they meet the technical specifications of the tender.

The registration process typically requires bidders to create an account on the designated government procurement portal. Following this, relevant documents and compliance certificates must be uploaded in the specified formats requested in the comprehensive tender guidelines.

Bidders are usually required to submit an Earnest Money Deposit (EMD) along with their bids. The amount and specific terms regarding the EMD are detailed in the tender documentation and are crucial for own commitment to the proposal.

The tender includes special provisions to support MSEs and startups, offering them competitive advantages in the bidding process. These benefits promote local industry growth and aim to facilitate increased participation from smaller entities in federal projects.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders