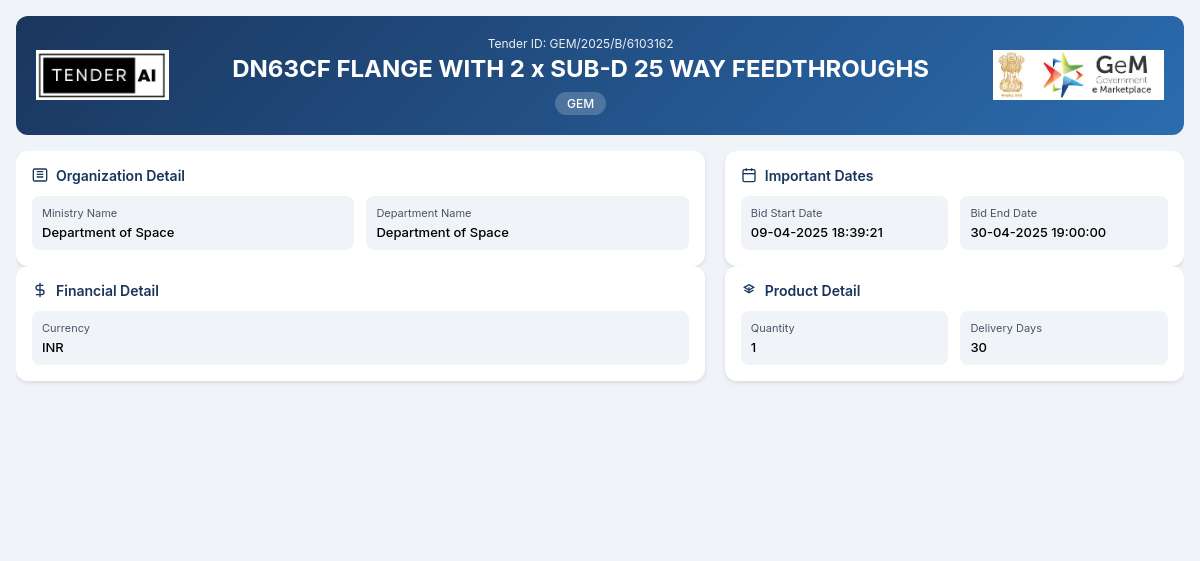

Tender Title: DN63CF FLANGE WITH 2 x SUB-D 25 WAY FEEDTHROUGHS

Tender Reference Number: GEM/2025/B/6103162

Issuing Authority: Department of Space

The DN63CF Flange with 2 x Sub-D 25 Way Feedthroughs tender invites qualified suppliers to submit bids for the provision of specialized components required for various applications within the aerospace and space technology sectors. This tender aims to procure a specific quantity tailored to meet stringent technical and operational standards, ensuring compatibility with ongoing projects developed by the Department of Space.

Scope of Work and Objectives

The objective of this tender is to supply DN63CF flanges equipped with dual Sub-D 25 way feedthroughs, designed to facilitate seamless integration in technical systems, focusing on reliability and adherence to safety protocols. Bidders must ensure that the provided flanges meet the applicable operational standards and specifications.

Eligibility Criteria

To participate in the tender, suppliers must meet specific eligibility criteria including:

- Being a registered entity recognized by relevant regulatory authorities.

- Proven experience in manufacturing or supplying similar components within the tech and aerospace sectors.

- Submission of updated legal and financial documents as part of the bid.

Technical Requirements

Bidders are required to provide:

- Detailed technical specifications of the DN63CF flange and Sub-D feedthroughs.

- Certification that all products meet the prevailing international quality standards.

- Product samples may be requested for assessment purposes.

Financial Requirements

All participating bidders must include comprehensive financial documentation which demonstrates their capability to fulfill the project requirements, including:

- A clear pricing structure.

- Policies related to payment milestones contingent on project phases.

Document Submission Details

Interested parties should submit their documents electronically or via the designated online portal as specified by the tender guidelines. Submissions must include:

- Completed bid forms.

- Required technical and financial documentation.

- Any additional certificates or declarations necessary for compliance.

Special Provisions

This tender also includes provisions for Micro, Small, and Medium Enterprises (MSEs) to promote inclusive participation. Benefits may include simplified processes and potentially reduced financial obligations during procurement phases.

Evaluation Process

The evaluation of bids will follow a structured process, assessing both the technical capabilities and financial proposals. Key criteria include:

- Compliance with technical requirements.

- Competitive pricing.

- Sustainability of the financial proposal.

- Delivery timelines.

Delivery Locations

Successful bidders will be required to deliver the DN63CF flanges to specified locations as per the awarded contract, coordinating closely with the Department of Space on timelines and logistics.

Contact Information

For further inquiries related to the tender or submission process, interested parties are encouraged to reach out directly to the Department of Space.

This tender aims to foster collaboration with industry leaders by ensuring high levels of quality and innovation in the aerospace sector. Suppliers who meet the above criteria and are committed to upholding rigorous standards are encouraged to apply and contribute to the visionary goals of the Department of Space.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

5 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity recognized by relevant authorities, demonstrating experience in manufacturing or supplying similar components, and submission of necessary legal and financial documents. Bidders must also adhere to specified technical standards related to the DN63CF flange and its components.

Bidders must provide comprehensive technical specifications detailing dimensions, materials used, and compatibility with existing systems. Certification confirming that the products meet industry standards is also required. Adhering to quality guidelines enhances the proposal’s credibility in the evaluation process.

Documents must be submitted electronically through the designated online system specified in the tender guidelines. Key components for submission include completed bid forms, relevant technical and financial documentation, and compliance certificates. Early preparation ensures a smooth submission process within the defined timelines.

Micro, Small, and Medium Enterprises (MSEs) may enjoy simplified procedures, reduced fees, and other incentives during the bidding process. Engaging with such provisions can enhance the participation of smaller entities, fostering support for equitable growth within the sector and compliance with local procurement regulations.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders