Tender Title: SUPPLY OF AXHD101 CARBON STEEL FORGED FITTINGS AND AXHD201 STAINLESS STEEL FORGED FITTINGS

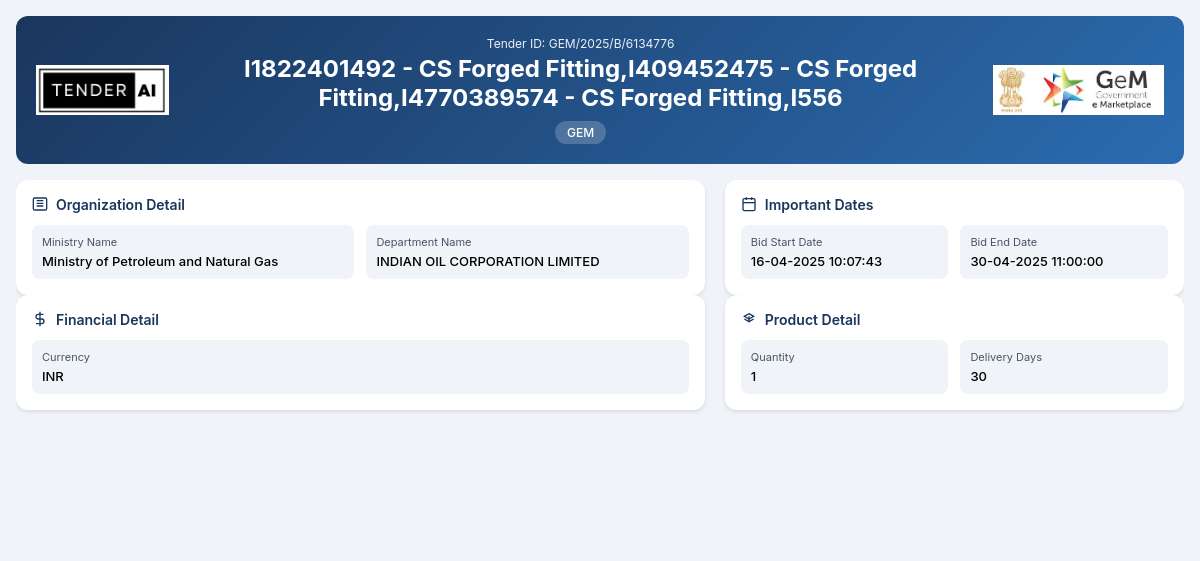

Reference Number: GEM/2025/B/6134776

Issuing Authority: INDIAN OIL CORPORATION LIMITED

Department: Ministry of Petroleum and Natural Gas

The scope of work for this tender encompasses the procurement and supply of AXHD101 Carbon Steel Forged Fittings and AXHD201 Stainless Steel Forged Fittings, which are essential components in various industrial applications. The goal is to enhance operational efficiency and maintenance capability through the provision of high-quality forged fittings.

Eligible participants in this tender must meet specific eligibility criteria. Organizations that can demonstrate registration as a legal entity and possess the necessary capabilities to fulfill the requirements of this tender will be considered. Furthermore, bidders might need to provide substantial evidence of past performance in similar contracts to maintain compliance and reliability standards.

On the technical requirements front, bidders will need to ensure that the supplied products conform to current industry standards. This includes compliance with specified quality standards and certifications required for carbon and stainless steel fittings. Documentation pertaining to quality assurance processes, along with testing methodologies, should be submitted to prove adherence.

The financial requirements entail bidders presenting a detailed breakdown of costs involved in the production and delivery of the mentioned fittings. Transparent pricing models are encouraged to facilitate seamless evaluation of bids based on value for money while ensuring compliance with the set budget parameters.

Interested bidders must follow specific document submission details. All submissions must be made electronically through the designated procurement platform, adhering to the accepted document formats outlined in the tender documentation. Proper submission is critical to ensuring that all bids are accounted for and evaluated accordingly.

There are special provisions aimed at supporting Micro, Small, and Medium Enterprises (MSEs) and startups, encouraging participation from these segments of the industry. Such benefits can include preferential bid considerations or financial support mechanisms aimed at leveling the playing field in competitive tender processes.

In terms of the evaluation process, bids will be scrutinized based on both technical and financial compliance. Evaluators will look for the alignment of proposals with specified requirements, including quality assurances, to ensure that the awarded contracts truly reflect the best value for the Indian Oil Corporation Limited.

Delivery locations will be specified in subsequent communications, detailing the required logistics for the procurement of fittings to ensure timely delivery to various project sites across operational regions.

For any queries and additional information, bidders are encouraged to reach out through the contact channels listed on the procurement platform. Clear and open communication is vital for clarity regarding any aspect of the tender.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

6 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC)

- Additional Doc 1 (Requested in ATC)

- Additional Doc 2 (Requested in ATC)

- Additional Doc 3 (Requested in ATC)

- Compliance of BoQ specification and supporting document *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements for this tender include being a registered entity in good standing and possessing the technical and financial capacity to deliver on the procurement of AXHD101 Carbon Steel Forged Fittings and AXHD201 Stainless Steel Forged Fittings. Organizations should also present previous experience with similar projects to ensure reliability and capability.

Bidders must provide relevant certificates that demonstrate compliance with industry standards for carbon and stainless steel products. This includes quality assurance certificates, test compliance reports, and industry accreditation that validate the supplier’s capability and credibility.

To participate, interested parties must initiate a registration process through the tendering platform, ensuring all required documentation is submitted. This includes business registration details, financial statements, and evidence of prior project delivery related to industrial fittings to authenticate their eligibility.

The tender documentation specifies particular document formats for submission, typically accepting formats such as PDF, DOCX, and Excel. Bidders must adhere to these specifications to ensure their submissions are validated and included in the evaluation process.

Successful bidders will be required to post a performance security to guarantee the fulfillment of contractual obligations. The performance security ensures that suppliers deliver the necessary fittings in accordance with the specifications stated within the tender and covers any damages in case of non-compliance.

These structured sections provide clarity and insight for interested bidders, effectively aligning with the tender’s operational framework while enhancing search engine visibility through keyword optimization.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders