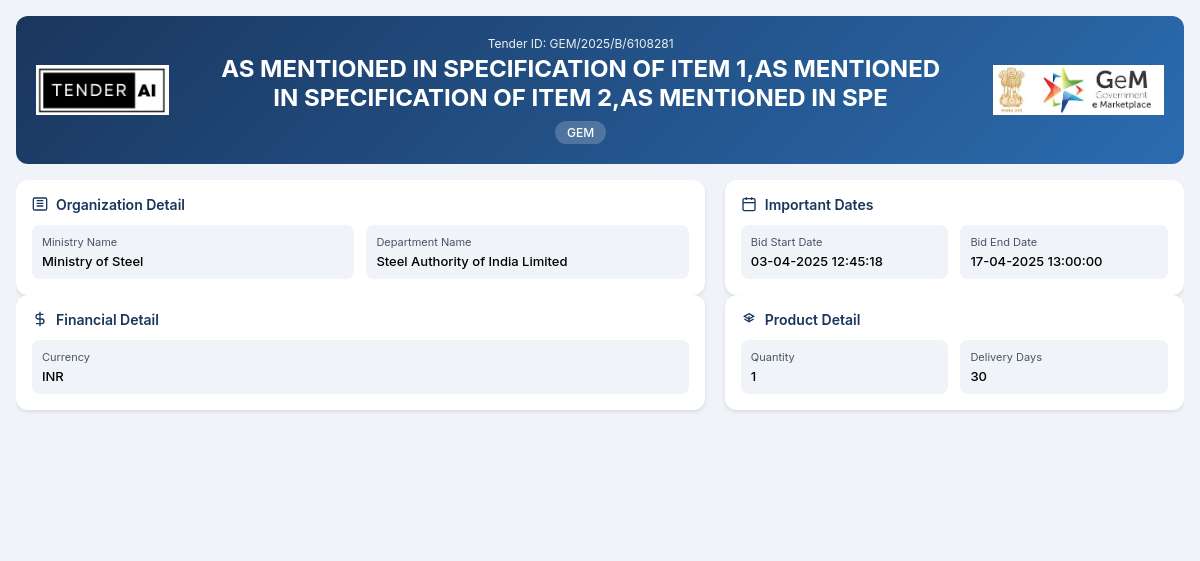

Steel Authority of India Limited Tender by Rourkela Steel Plant (GEM/2025/B/6108281)

AS MENTIONED IN SPECIFICATION OF ITEM 1,AS MENTIONED IN SPECIFICATION OF ITEM 2,AS MENTIONED IN SPE

Tender Timeline

Tender Title: PUMPS FOR COOLING WATER SYSTEM OF SP 3

Tender Reference Number: GEM/2025/B/6108281

Issuing Authority: Steel Authority of India Limited (Ministry of Steel)

The PUMPS FOR COOLING WATER SYSTEM OF SP 3 tender aims to procure high-quality pumps that will serve critical functionalities in the cooling water system. The objective of the tender is to enhance operational efficiency and system reliability within the Steel Authority's facilities. Interested vendors are invited to participate in this procurement process, adhering to the specifications and conditions outlined in the tender documents.

Scope of Work and Objectives

The primary scope of work comprises the supply, installation, and commissioning of pumps specifically designed for cooling water systems. The main objectives of this venture include:

- Ensuring the delivery of pumps that meet operational performance standards.

- Enhancing system reliability and efficiency.

- Complying with predetermined specifications and quality standards.

Bidders must demonstrate a thorough understanding of the cooling water systems, as well as the ability to provide comprehensive support from supply through to installation and after-sales services.

Eligibility Criteria

To qualify for the tender, bidders must meet certain eligibility criteria:

- The bidder must be a registered entity authorized to conduct business in India.

- Previous experience in supplying similar equipment or services will be considered beneficial.

- Compliance with all applicable local laws and regulations is mandatory.

Technical Requirements

The technical requirements include, but are not limited to, the following:

- Certified performance data demonstrating the efficiency and durability of the proposed pumps.

- Compliance with relevant industry standards and certifications.

- Detailed specifications aligned with the tender requirements, including capacity, horsepower, energy efficiency, and longevity.

Financial Requirements

Financial stability is paramount for eligibility. Bidders must submit their financial statements that demonstrate the financial capability to sustain the procurement and subsequent services associated with installation and support.

Document Submission Details

All documents must be prepared and submitted following specified formats outlined in the tender documentation. Bidders should ensure the completion of all necessary forms and inclusion of all required certificates and proof of registration to validate their submission.

Special Provisions

This tender makes provisions to encourage participation from Micro, Small, and Medium Enterprises (MSEs) and startups. Specific benefits include:

- Relaxed qualification criteria for MSEs.

- Possible price preference for eligible bidders.

Evaluation Process

The evaluation process will consider both financial and technical proposals:

- Technical Evaluation: This component includes assessment against the detailed specifications and requirements.

- Financial Evaluation: This will assess pricing components alongside value for money and financial stability.

Delivery Locations

The successful vendors will be required to deliver the pumps to specified locations as indicated in the tender documents.

Contact Information

For further inquiries, vendors can reach out to the Steel Authority of India Limited through the communication channels available within the tender documentation.

Additional Information

This tender aims to streamline transparent procurement while maintaining quality and service integrity. Vendors must ensure that their submissions adhere to the guidelines and specifications set forth to avoid disqualification. To ensure compliance, a thorough review of all requirements is recommended before submission.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

5 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC)

- Additional Doc 1 (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Corrigendum Updates

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity qualified to operate within India, along with demonstrable experience in supplying similar items or services. Compliance with all relevant local regulations is crucial. Interested bidders should provide complete documentation, reflecting their operational credentials and a history of successful engagement in comparable projects.

The technical specifications for the pumps include compliance with industry standards regarding performance and energy efficiency. Bidders should provide certified performance data and product specifications that detail capacity, horsepower, and projected longevity. Adherence to quality standards will hold significant weight during the evaluation phase.

Bidders must demonstrate financial stability by submitting their financial statements. This documentation should reflect their ability to support the procurement process, including supply, installation, and ongoing service commitments associated with the project. Compliance to pricing proposals that ensure value for money is also critical during evaluation.

Documents must be submitted in the specified formats outlined in the tender documentation. Accepted document formats typically include PDF or Word files as specified. Bidders should ensure that all required certifications and proofs of registration accompany their submissions to avoid disqualification.

MSEs stand to gain significant advantages, such as relaxed qualification criteria and potential price preferences in assessments. The tender encourages participation from MSEs to promote inclusive procurement and help foster growth among smaller businesses, thus supporting the broader ‘Make in India’ initiative aimed at boosting local industries.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders