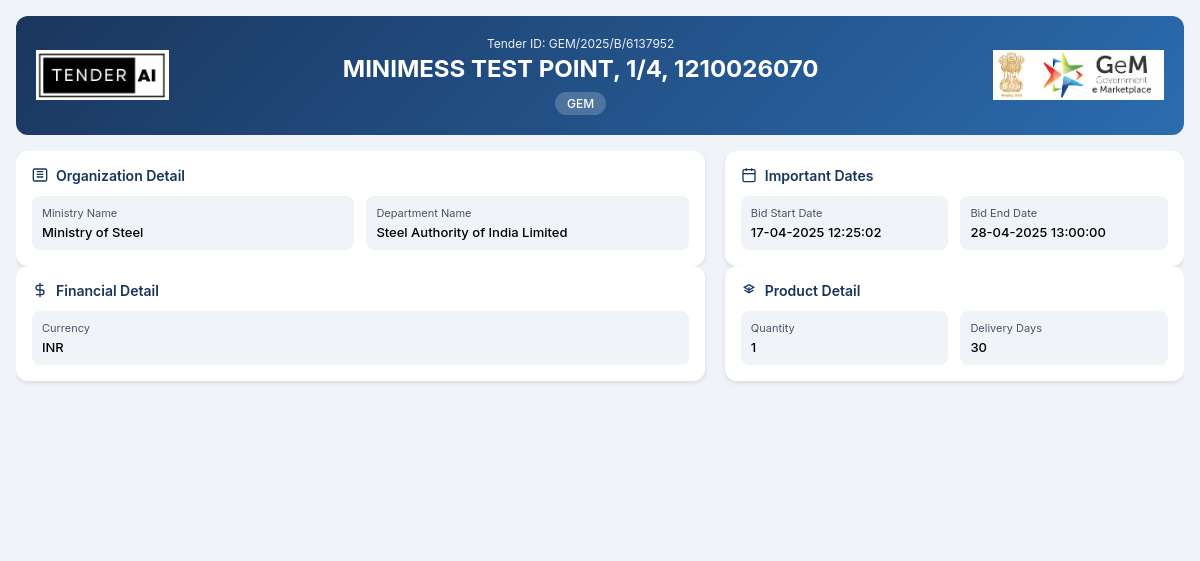

Steel Authority of India Limited Tender by Bhilai Steel Plant (GEM/2025/B/6137952)

MINIMESS TEST POINT, 1/4, 1210026070

Tender Timeline

Tender Title: MINIMESS TEST POINT

Reference Number: GEM/2025/B/6137952

Issuing Authority/Department: Steel Authority of India Limited under the Ministry of Steel

The MINIMESS TEST POINT tender concerns the procurement of materials essential for the operation and calibration of testing apparatus crucial in the steel manufacturing sector. This tender intends to consolidate the quality assurance processes within the Steel Authority of India Limited, ensuring that testing points meet rigorous industrial standards.

Scope of Work and Objectives

The primary objective is to provide 400 units of MINIMESS TEST POINTS, particularly of the model number 1/4, 1210026070. Vendors will be expected to supply these components in adherence to strict technical specifications, thus facilitating accurate pressure measurements and evaluations across various processes in the steel production industry.

Eligibility Criteria

To be eligible to participate in this tender, potential bidders must be registered entities with a valid GST, and must have experience in supplying similar materials to governmental or reputable organizations in the past. Adherence to safety regulations and standards is also critical.

Technical Requirements

Bid submissions must include evidence that the offered products comply with the necessary quality standards pertaining to their specifications. This includes ISO certifications or equivalent that demonstrate a commitment to upholding the highest standards of compliance and performance in manufacturing and testing processes.

Financial Requirements

Bidders must demonstrate financial stability through past audited financial statements. An Earnest Money Deposit (EMD) will be mandated, the details of which will be provided in the tender documents, ensuring that only serious bids are submitted for consideration.

Document Submission Details

Prospective bidders are required to submit all necessary documents, including the technical specifications and financial statements, electronically via the designated e-procurement portal associated with this tender. Formatting and submission guidelines will be explicitly stated in the tender documentation to ensure uniformity.

Special Provisions

To recognize and encourage participation from Micro, Small, and Medium Enterprises (MSEs) and startups, there will be specific provisions in the evaluation process to bolster their bidding capacities. This adherence to governmental policies aims to promote local manufacturing and strengthen the domestic economy.

Evaluation Process

The evaluation process will be transparent, following a two-stage assessment: the first stage will evaluate the technical compliance of the submitted bids, and the second stage will review the financial proposals based on predefined scoring criteria.

Delivery Locations

Successful bidders must be capable of delivering the MINIMESS TEST POINTS to specified locations as outlined in the tender documentation, ensuring a seamless supply chain for operationalization.

Contact Information

For any further inquiries regarding the tender, potential bidders are encouraged to reach out to the designated points of contact within the Steel Authority of India Limited, whose details will be included in the tender documentation.

This tender presents a valuable opportunity for suppliers experienced in the steel industry to collaborate with a prominent agency, thereby advancing their business interests while contributing to the metallurgical standards within the country.

General Information

Financial Information

Evaluation and Technical Information

Tender Documents

5 DocumentsDocuments Required from Seller

- Certificate (Requested in ATC)

- OEM Authorization Certificate

- Additional Doc 1 (Requested in ATC)

- Additional Doc 2 (Requested in ATC) *In case any bidder is seeking exemption from Experience / Turnover Criteria

- the supporting documents to prove his eligibility for exemption must be uploaded for evaluation by the buyer

Similar Tenders

Frequently Asked Questions

The eligibility requirements include being a registered entity with a valid GST number and having prior experience in supplying similar materials to governmental or reputable organizations. Participants must also demonstrate compliance with safety regulations and technical specifications outlined in the tender.

Bidders must provide certification that attests to the technical specifications of the offered products. This includes necessary ISO certifications or industry-standard assurances that validate the compliance of the materials with quality expectations and manufacturing standards.

To register for the tender, participants must complete their registration on the designated e-procurement portal, submit their offers along with required documentation, and ensure that all submissions follow the specified formats outlined in the tender guidelines.

A performance security is typically required to be submitted by the successful bidder, ensuring compliance with the terms of the contract. The amount and specifics surrounding the performance security will be elaborated upon in the tender documentation.

MSEs can benefit from special provisions designed to encourage their participation, such as relaxed qualification criteria and additional evaluation scores during the selection process. This aims to provide a more level playing field and promote local manufacturing in line with governmental initiatives.

Probable Bidders

Get Tender Alerts

Get notifications for similar tenders